If you are looking wholesale lighting solutions, click here.

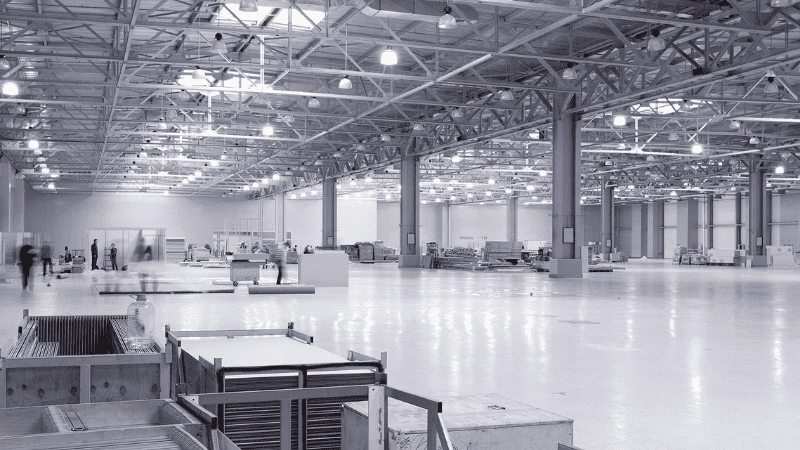

Warehouses need different types of lighting than other commercial buildings because the ceiling height is much higher, and the space is usually larger.

Proper lighting is important for any warehouse operation as it can greatly impact the facility’s safety, productivity, and overall efficiency.

In this guide, we will discuss how to determine the number of lighting fixtures needed for your warehouse and why it’s important to get it right. So, let’s get right in.

As the name suggests, warehouse lights are specialized lighting solutions designed to illuminate vast spaces such as warehouses and distribution centers.

These lights are specifically designed to cater to the unique needs of such environments, which typically include high ceilings, large floor areas, and varying ambient light levels.

Unlike traditional office or residential lighting, warehouse lights require a higher lumen output to illuminate a larger space adequately.

They should offer consistent, bright light to ensure workers’ safety and boost productivity. These lights are typically more robust and durable, made to withstand the rigors of a working warehouse environment.

There are various types of warehouse lights available in the market, each with its own unique features and benefits. Some of the most common types include:

High bay lights are the most common type of warehouse lighting solutions. They are ideal for general lighting in warehouses, as they can cover a large area with consistent light.

High bay lights are typically mounted on the ceiling or suspended from it and come in various shapes, including round, linear, and UFO.

Low bay lights are another type of warehouse lighting solution, but unlike high bay lights, they are better suited for areas with lower ceilings (typically under 20 feet).

While they have a similar design to high bay lights, they emit a more concentrated light, making them ideal for smaller, more confined spaces.

Linear strips are long, narrow fixtures that provide uniform light distribution. They are typically mounted on the ceiling and offer excellent general lighting.

Linear strips can also supplement other types of warehouse lights, providing additional light in specific areas.

Flood lights are powerful, high-output fixtures that provide intense illumination over a large area. They are commonly used for outdoor lighting but can also be used indoors for warehouses with high ceilings.

Floodlights come in various sizes and shapes, including traditional floodlights and more compact LED versions.

Proper lighting in a warehouse is not just about illumination; it’s a vital component that affects safety, productivity, and efficiency.

The right warehouse lighting is an unsung hero for increasing productivity and efficiency. Imagine a well-illuminated workspace where every item is clearly visible, reducing the time to locate and move goods.

Not only does it speed up operations, but it also minimizes errors, boosting the overall workforce efficiency.

Appropriate warehouse lighting is not merely a choice but a necessity for ensuring the safety of employees.

Poorly lit areas can lead to accidents or mishaps, particularly in a bustling environment like a warehouse. High-quality lighting fixtures help reduce shadows and dark corners, minimizing risks and ensuring a safer work environment.

A well-lit warehouse using energy-efficient LED lights can significantly reduce energy consumption and monthly electricity bills.

Imagine your savings by switching from traditional lighting to LED technology. Furthermore, energy-efficient lighting reduces greenhouse gas emissions, contributing to a greener and more sustainable environment.

This essential query goes beyond mere numbers; it involves understanding the unique lighting requirements of your warehouse space.

Next, we will introduce 5 factors that affect the selection of the number of warehouse lighting fixtures and how to choose the required quantity in these 5 aspects:

When determining the lighting fixtures needed for your warehouse, consider two key measurements: lux and footcandles. These units measure the light reaching a specific area, with lux being the metric unit and footcandles being the imperial unit.

One footcandle equals 10.764 lux and is typically used to measure light levels in a warehouse setting.

For example, a typical warehouse may require light levels between 20-30 footcandles for general lighting and 50-100 footcandles for task-specific areas. However, more footcandles or lux are needed for increased brightness and productivity.

For warehouse lighting, lumens are crucial in determining the overall brightness of the light fixtures. Lumens quantify the illumination level produced by a lighting fixture, with higher lumens equating to brighter lighting.

You can easily calculate lumen using the following formula:

( Lumens = Area (square metres) x Lux)

For instance, a typical LED warehouse light may have a lumen output ranging from 12,000 to 40,000 lumens, depending on the fixture’s size and power.

Choosing the right lumens is critical in ensuring that your warehouse is adequately lit without being overly bright. More lumens are typically needed for larger or high-ceiling spaces, while smaller areas or task-specific lighting require fewer lumens.

Determining the appropriate spacing between lighting fixtures is crucial for achieving uniform and adequate illumination in your warehouse. The spacing is usually calculated by considering the space’s area and the fixtures’ intensity.

First, you can use the rule of thumb that the distance between fixtures should be approximately the same as the height from the floor to the fixtures.

For example, if your fixtures are mounted 20 feet high, they should be about 20 feet apart. However, this is just a guideline and may need to be adjusted based on your specific needs.

The fixture’s light spread (the area that a fixture can illuminate) and the lumen output can also affect the spacing. Higher lumen output or a wider light spread may allow you to space the fixtures further apart without sacrificing light quality.

Remember, the goal is to prevent dark spots and ensure a consistent, even light throughout the warehouse.

Therefore, it may be worth consulting with a lighting specialist to determine the optimal fixture spacing for your warehouse layout and lighting needs.

Your warehouse layout and any potential obstructions can also influence the number of lighting fixtures you need. For instance, areas with high shelving, large equipment, or densely packed inventory might require additional lighting to maintain visibility.

Consider the height of your racking systems and any areas in shadow or blocked from the main light sources.

Additional spot or task lighting may be necessary in these areas. Ensure your lighting plan accommodates your warehouse layout and any potential obstructions to achieve optimal illumination.

The type of activities conducted in your warehouse and specific work areas also play a crucial role in determining the number of industrial warehouse lighting. Different tasks require different levels of lighting.

For example, areas where fine-detailed work is carried out, such as pack and wrap stations or quality control areas, will likely require higher lighting than general storage areas.

Understanding your warehouse’s operations and identifying specific work areas can help you tailor your lighting plan effectively and ensure that every area has appropriate illumination for the tasks being performed.

While determining the number and type of lights is essential, there are other factors that significantly impact the effectiveness of warehouse lighting.

Light distribution patterns are crucial in achieving adequate illumination and reducing glare, shadows, and dark spots. Choosing the right lighting distribution pattern is key to ensuring an evenly lit warehouse without creating any safety hazards.

Some common lighting distribution patterns include:

Color temperature refers to light’s perceived warmth or coolness, measured in Kelvin (K). It can significantly impact visibility and productivity in your warehouse, so choosing the right color temperature is crucial.

Some common color temperatures used for warehouse lighting include:

Correlated Color Temperature (CCT) is another measure of color temperature, with a scale ranging from 1000 to 10,000K. Like color temperature, a higher CCT indicates a cooler light and a lower CCT indicates a warmer light.

Choosing the right CCT can help create an optimal working environment for your warehouse employees and improve visibility.

It’s essential to consider the type of tasks being performed in each area when selecting the right CCT for your warehouse lighting.

LED light fixtures have become the preferred lighting solution for warehouses due to their energy efficiency, long lifespan, and low maintenance costs.

LEDs offer a range of color temperatures and distribution patterns, making them highly versatile for warehouse lighting.

Moreover, with technological advances, LEDs can now provide higher lumen output at lower wattages than traditional light sources such as fluorescent or metal halide lamps.

This means you can achieve the same or better illumination level with fewer fixtures, resulting in lower energy costs and greater cost savings in the long run.

Depending on the height and layout of your warehouse, the best lighting option may vary.

Depending on your ceiling height and distribution needs, you can opt for LED high-bay or low-bay lighting fixtures. When selecting the best lighting option, it’s also essential to consider the activities conducted in your warehouse.

OSHA advises maintaining proper illumination levels in warehouses. General spaces should have an average of 5-foot candles, while areas requiring fine attention to detail should have 10-foot candles.

Moreover, emergency exits and aisles should be well-lit to ensure safety during an emergency. It’s essential to consult with a lighting specialist to ensure your warehouse meets all OSHA requirements for lighting.

Choosing the right lighting for your warehouse is crucial to providing a safe and productive work environment.

You can develop an effective lighting plan that meets your specific needs. In addition, opting for LED fixtures can provide long-term cost savings and energy efficiency for your warehouse.

With the right lighting plan in place, you can improve visibility and productivity in your warehouse while maintaining a safe working environment for your employees.

Proper lighting in your warehouse is essential for ensuring the safety and productivity of your employees. Risun offers various LED lighting solutions for warehouses, including high-bay and low-bay fixtures, to suit your needs.

Whether you are looking for energy-efficient lighting for your warehouse or a custom plan for your unique warehouse layout, our team of experts can help. Contact us today to learn more about our warehouse lighting solutions!

Comprehensive Lighting Solutions for MRO Wholesalers and Professionals

send your inquiry

Hi, I'm the author of this post, and I have been in this field for more than 15 years. If you want to wholesale lighting fixtures or lighting related product, feel free to ask me any questions.

Learn More >>Download our catalog to view all of our lighting products.

Ready to get started ?

Send Your InquiryOur team will get back to you promptly

please

download

Get notified about new products

Our team will get back to you promptly!

Add your first comment to this post