If you are looking wholesale lighting solutions, click here.

Are you a lighting manufacturer, wholesaler, or electrician deciding between E26 and E27 bulbs? Though they look alike, small differences impact compatibility, safety, and sourcing decisions.

This guide helps B2B buyers understand whether E26 and E27 bulbs are interchangeable, what technical factors to consider, and which option suits different markets. The right choice can improve performance and efficiency in your lighting systems.

The “E” in E26 and E27 refers to the Edison screw base, a widely used standard for light bulbs worldwide. It was named after the famous scientist, Thomas Edison.

This screw-in base is the most common socket for all types of lighting. Its simple and reliable design has kept it popular for over a century.

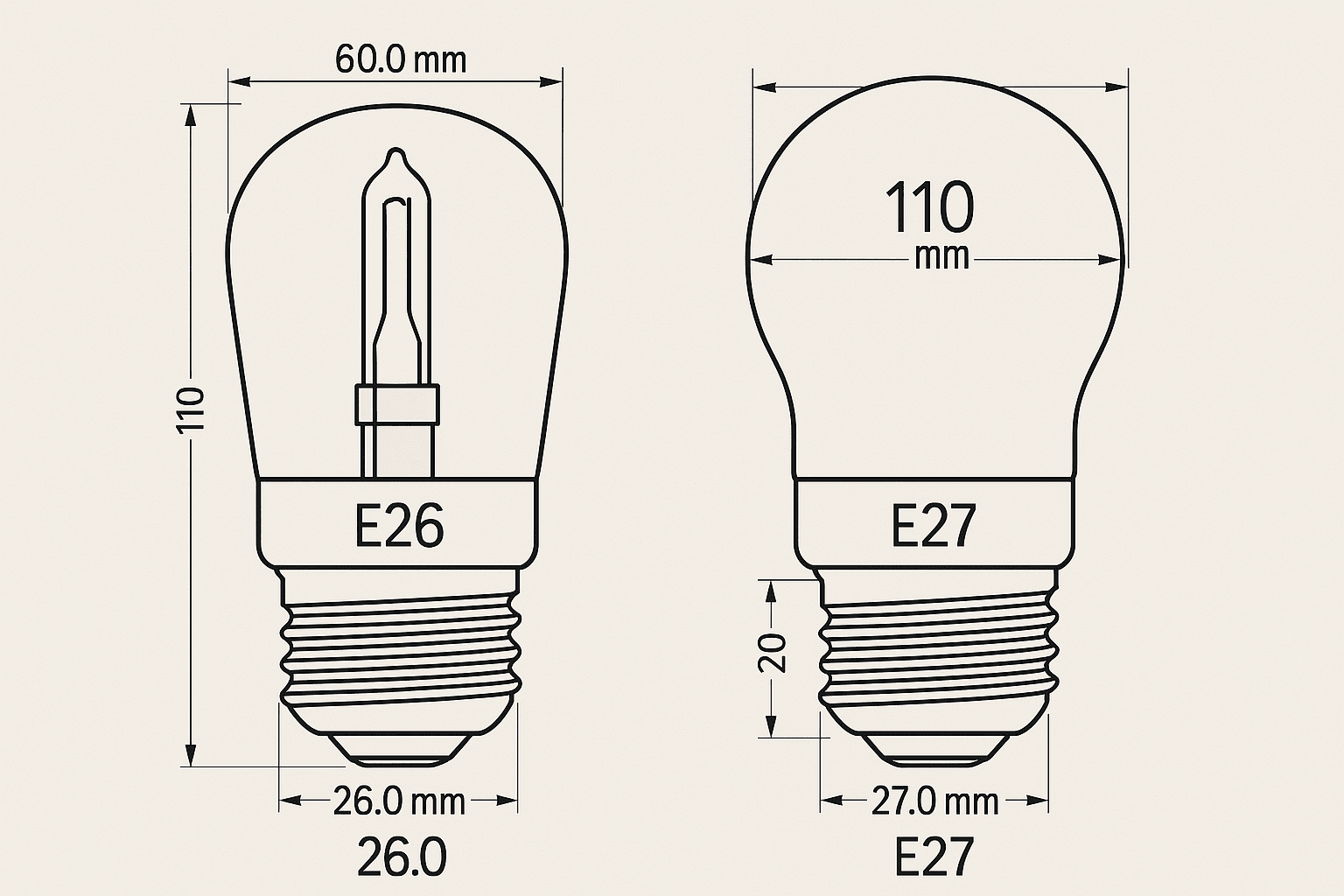

Edison screw bases are categorized by their diameter. It measured in millimeters at the widest part of the screw thread. Therefore, E26 bulbs measure precisely 26mm in diameter, while E27 bulbs measure 27mm.

E26 bulbs are commonly used in the U.S., Canada, and Japan for both commercial and residential lighting.

They are found in offices, retail stores, warehouses, hotels, and industrial spaces across North America.

These bulbs are designed for fixtures that operate on 110-120V electrical systems. They are standard in markets following North American electrical standards.

E27 bulbs are mainly used in Europe, Asia, and Australia, where electrical grids run on 220- 240V. They are standard in factories, public buildings, outdoor lighting, and high-voltage commercial applications.

E26 and E27 bulbs often fit into each other’s sockets.

But their electrical requirements differ. Mixing them can cause performance issues, safety risks, and a shorter lifespan. This small difference reflects two major global electrical standards.

The 1mm diameter difference may seem minor but can cause fitting issues. An E26 bulb may not fully screw into an E27 socket, leading to loose connections and flickering. An E27 bulb may feel tight in an E26 socket, risking damage over time.

These issues are worse in settings where bulbs may loosen. Such as areas with vibration or temperature changes. In large-scale lighting, even small connection failures can lead to high maintenance costs.

The most critical difference between these bulb types relates to their voltage:

Some E26 bulbs can handle up to 250V. However, voltage mismatches can cause overheating, a shorter lifespan, or failure. In commercial lighting, these issues can disrupt operations and lead to serious consequences.

Using an E26 bulb in a 220- 240V socket can cause short circuits, overheating, or early failure. It can also damage fixtures or materials.

Businesses should always check voltage compatibility before making bulk purchases for international use.

In industrial settings, proper voltage matching is crucial. Replacing bulbs in hard-to-reach or hazardous areas is highly expensive. It adds cost for labor and downtime, not just the bulb itself.

Regional differences extend to the governing standards for these products:

Compliance with North American and European regulations is essential for international distribution. These certifications reflect different safety standards and testing protocols across markets.

| Feature | E26 Bulb | E27 Bulb |

|---|---|---|

| Base Diameter | 26mm | 27mm |

| Common Voltage | 120V | 220V to 240V |

| Threading Standards | ANSI (American) | IEC (International) |

| Regions | U.S., Canada, Japan | Europe, Asia, Australia |

| Applications | Offices, retail stores, warehouses, hotels, industrial spaces | Factories, public spaces, outdoor lighting |

| Compatibility | Sometimes Interchangeable | Sometimes Interchangeable |

North America and Japan use a lower voltage standard. That is why E26 bulbs are designed for 110-120V circuits. The voltage is important for the internal components of the bulb.

Such as filaments in incandescent bulbs or driver circuits in LEDs. These components are calibrated for safe and efficient operation at this voltage range.

European and Asian electrical grids deliver about twice the voltage of American systems. Therefore, E27 bulbs are rated for 220- 240V. Their internal components can handle this higher voltage without overheating or failing prematurely.

Installing an E26 bulb in a 220-240V system can cause overheating, reduce its lifespan, or create a fire hazard. Procurement professionals should always check voltage requirements when sourcing E26 or E27 bulbs.

E26 and E27 bulbs will physically fit into each other’s sockets in most cases. However, differences in base height and threading may cause loose connections.

This mechanical interchangeability often creates confusion, as the bulbs look nearly identical.

However, physical fitness alone does not ensure safe or optimal operation. This is important in commercial settings where lighting affects productivity, energy costs, and maintenance.

An E26 bulb used in an E27 socket is generally safe only if the voltage matches, such as in a 120V circuit with an E27 socket. Using an E26 bulb (120V) in a 220- 240V system can be dangerous.

The bulb may burn out instantly or overheat, creating a fire hazard. Modern LED bulbs with wide-range voltage drivers (100- 240V) can work in both sockets if they fit. However, always check regulatory compliance.

For B2B buyers, incorrect voltage specifications can lead to significant problems:

Pro Tip: When placing bulk orders, clearly specify voltage needs and ask for compliance certificates. For international use, create separate SKUs for E26 and E27 bulbs to avoid mix-ups.

The brightness of a bulb depends on wattage, lumens, and efficiency rather than just the socket type. However, the voltage difference between E26 and E27 bulbs may impact performance.

E26 bulbs (120V) have lower wattage limits and may not produce as much light output in high-powered applications. E27 bulbs (220V-240V) can support higher wattage levels in industrial and outdoor lighting.

Use E26 bulbs in all North American retail locations and office buildings. These bulbs match the standard voltage in these regions. Your maintenance staff will find replacements easily.

Specify E27 bulbs for your European and Asian commercial facilities. This ensures proper voltage compatibility with local electrical systems.

Global retail chains should develop clear lighting standards for each regional market. This approach maintains your brand appearance while respecting electrical differences.

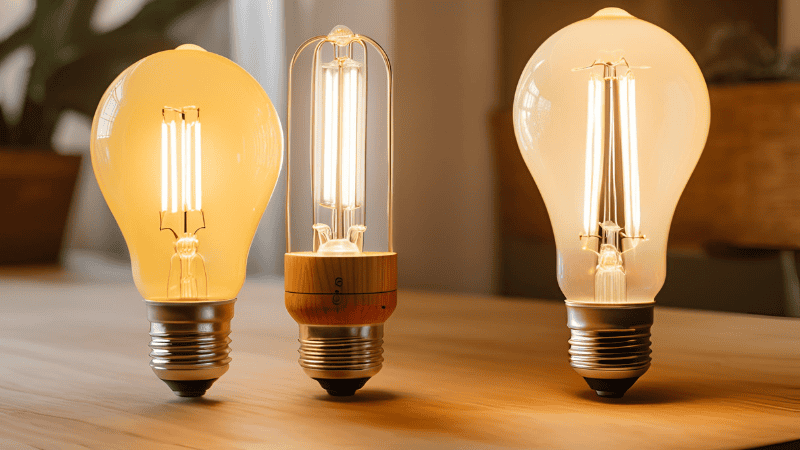

Consider LED options with universal voltage capabilities for your global operations. These bulbs work in both 110V and 220V systems without modification. They simplify procurement and reduce inventory confusion.

Large-scale industrial projects must verify voltage compatibility before installation begins. This simple step prevents costly electrical failures across your facility. It also protects expensive equipment from damage.

Outdoor lighting installations perform best with bulbs that exactly match local specifications. The right bulbs minimize maintenance visits to remote locations. They also extend the lifespan of your lighting infrastructure.

Critical infrastructure deserves backup lighting options that meet regional standards. These redundant systems ensure continuous operation during emergencies.

Industrial applications in hazardous environments must comply with regional certification standards. No exceptions can be made for these safety requirements. Your insurance coverage may depend on this compliance.

Companies selling in multiple markets should stock both E26 and E27 versions of their lighting products. This approach satisfies customers in all regions without compromise.

Equipment manufacturers benefit from designing fixtures compatible with both bulb types. These universal fixtures simplify your product line and reduce manufacturing complexity.

Distribution centers serving multiple regions need clear inventory separation systems. Proper labeling prevents expensive cross-shipping errors between markets. It also improves customer satisfaction.

Consider dual-voltage bulbs whenever possible to streamline your inventory management. These versatile products reduce storage requirements and simplify training for your sales team.

North America and Japan use E26 bulbs with 110- 120V systems. This standard is consistent throughout these regions for commercial buildings.

Europe, Asia, and Australia rely on E27 bulbs designed for 220- 240V electrical systems. The voltage difference is significant and affects bulb performance and safety.

Companies with multinational operations should create clear procurement guidelines for each region. These guidelines help prevent ordering mistakes and ensure proper installation.

They should specify both bulb type and voltage requirements for each facility location. Local maintenance teams need this information to make correct purchasing decisions.

Traveling equipment and mobile installations present unique challenges for lighting compatibility. Universal voltage solutions offer the best approach for these situations.

These specialized bulbs work across different electrical systems without modification. They eliminate the need to swap bulbs when moving equipment between regions with different standards.

Energy-efficient E26/E27 LED bulbs offer significant savings in hospitality settings. These bulbs perform well in areas where lights stay on for many hours each day. Consistency in color temperature helps maintain your brand image across different locations.

Your guests will experience the same visual atmosphere in every property. When calculating costs, look beyond the initial purchase price. Consider both energy usage and how often bulbs need replacement. These factors contribute to the true ownership cost over time.

Always verify the IP rating before making bulk purchases for construction projects. Check voltage specifications carefully to ensure compatibility with your systems. Compliance certifications protect you from liability and ensure worker safety.

Harsh environments require special attention to bulb durability. Make sure the bulbs you select can withstand dust, moisture, and extreme temperatures. Extended warranty options make sense for lights installed in hard-to-reach places.

Design your fixtures to work with both E26 and E27 bulbs whenever possible. This approach simplifies your product line for global markets. Your customers will appreciate the flexibility. Clear documentation prevents confusion about voltage requirements.

Include this information prominently in product literature and packaging. Universal voltage electronics solve many compatibility issues. These components allow your products to function properly across different electrical systems worldwide.

E26 and E27 bulbs look similar but have a 1mm base difference. This small detail separates major global electrical standards. For B2B buyers, understanding size, voltage, compliance, and regional differences is crucial.

Voltage compatibility is key. Using the wrong bulb can cause safety risks, failures, and high costs. Businesses operating internationally should set clear specifications to avoid cross-shipping errors.

They should work with knowledgeable suppliers to avoid mistakes. Always choose certified suppliers who meet ANSI, IEC, UL, and CE standards for your market.

Being a top provider of industrial and commercial lighting, we provide E26 and E27 bulbs for many uses. See our product list for high-quality lighting solutions.

Our engineering team understands the critical differences between regional standards. They can help you select the perfect lighting solution for any application.

Need expert guidance or bulk purchases? Contact our team for lighting solutions tailored to your business needs.

Comprehensive Lighting Solutions for MRO Wholesalers and Professionals

send your inquiry

Hi, I'm the author of this post, and I have been in this field for more than 15 years. If you want to wholesale lighting fixtures or lighting related product, feel free to ask me any questions.

Learn More >>Download our catalog to view all of our lighting products.

Ready to get started ?

Send Your InquiryOur team will get back to you promptly

please

download

Get notified about new products

Our team will get back to you promptly!

Add your first comment to this post