If you are looking wholesale lighting solutions, click here.

Metal Halide (MH) lamps fall under high-intensity discharge (HID) light technology. MH lamps find far-reaching applications in commercial and industrial lighting requirements requiring powerful, efficient, and long-duration illumination.

With organizations adopting newer technologies, it is essential to understand how MH lamps work and differ from new technologies such as LEDs.

A Metal Halide lamp is an HID lamp, which utilizes a unique mixture of gases—xenon, a noble gas, metal halides, sodium, and mercury to create a highly intense white light. They are also called Mercury lamps. They come in different bulb sizes, shapes, types, and codes.

When energized, the electric current attacks the gas mixture within the lamp to create a highly intense, highly efficient, and concentrated beam. This makes MH lamps ideal for areas that need proper sight.

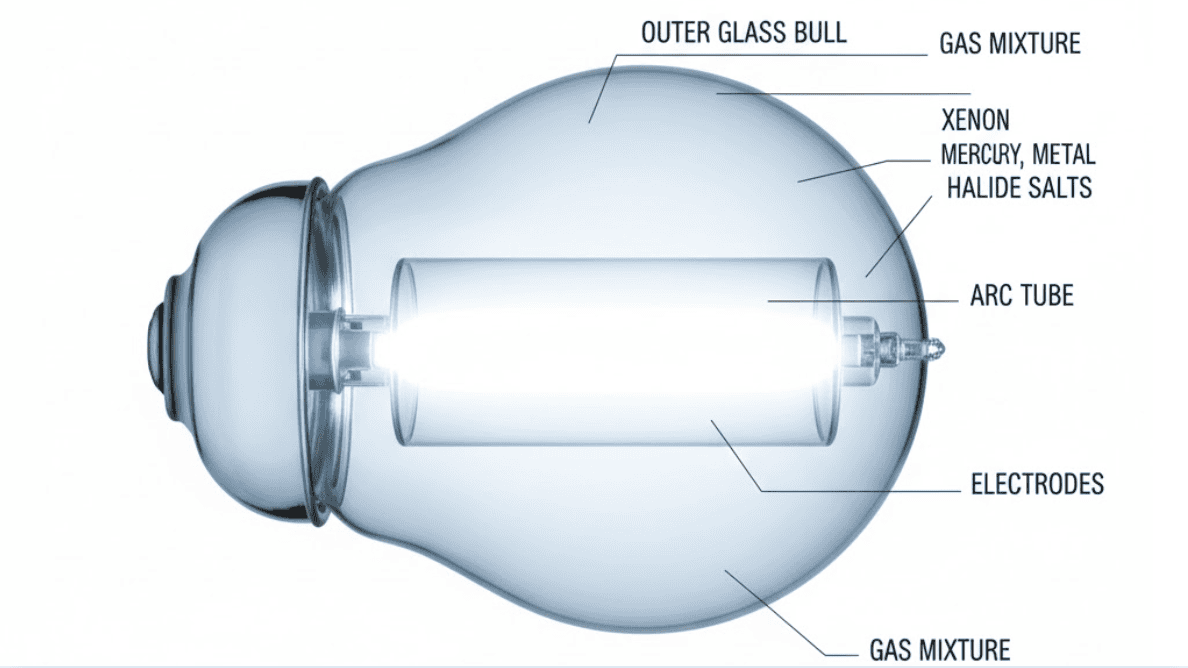

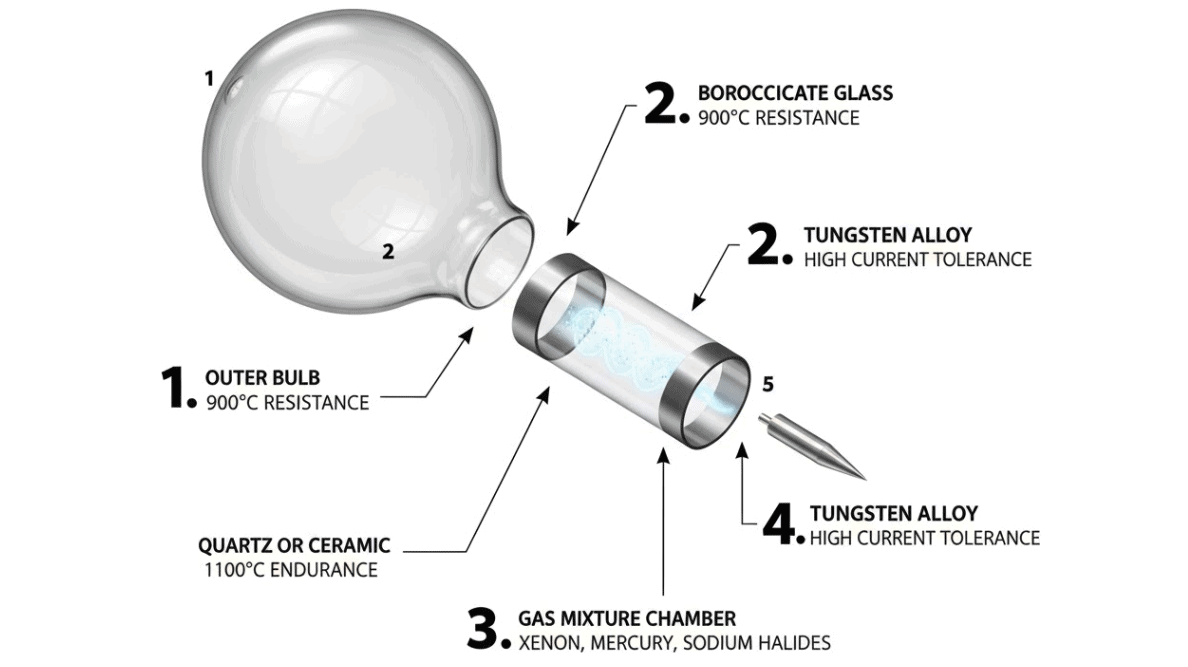

The essential elements of a Metal Halide (MH) lamp are assembled to produce white, energy-efficient light by combining special materials and techniques. Metal Halide components are:

The outer bulb is generally borosilicate glass, which is thermally shock-resistant and also withstands high temperatures. The outer bulb acts as a protective envelope and filters out unwanted ultraviolet (UV) radiation.

The arc tube is within the outer bulb and holds metal halide salts and gases. It is typically ceramic or quartz, capable of supporting extremely high operating temperatures.

Two electrodes are placed on the two ends of the arc tube. When electricity flows through the electrodes, it creates an arc that vaporizes the gas mixture and releases light.

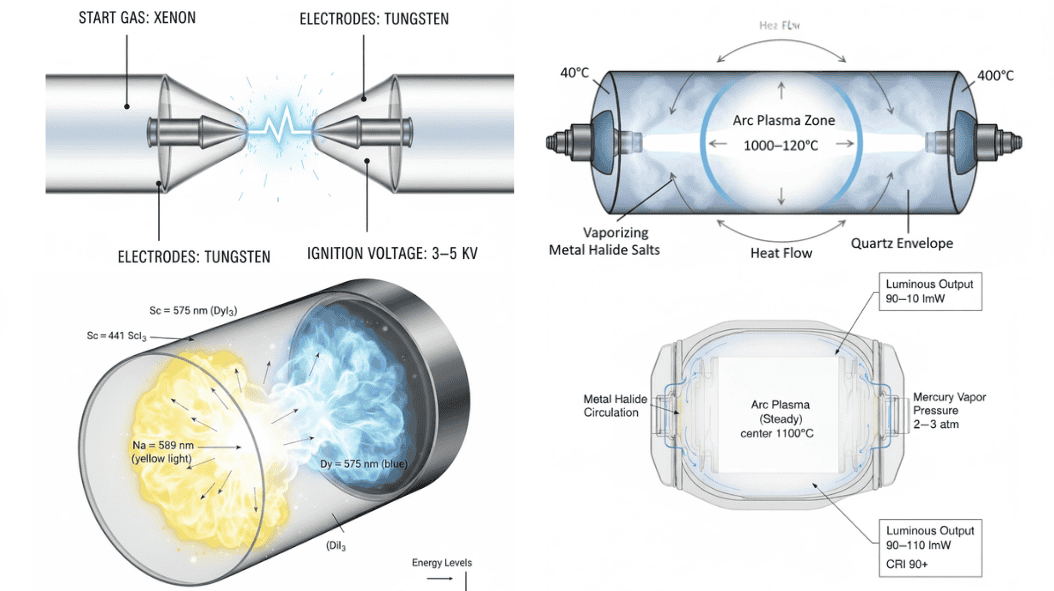

The ignition process starts when an electric current is allowed to flow through the electrodes. This causes the gas within to be heated up, vaporizing and combining with the metal halide compounds and emitting brilliant white light.

Compared to incandescent lamps, in which light is produced by the thermal energy of a filament, Metal Halide lamps generate light because of a chemical reaction in an arc tube that contains gas.

The instant the arc is struck, the arc tube warms up, and for a short while, metal halide salts are converted into plasma and emit a beam of high intensity.

This technology provides higher lumen output and color rendering index and is best suited to applications with high light intensity and visual acuteness.

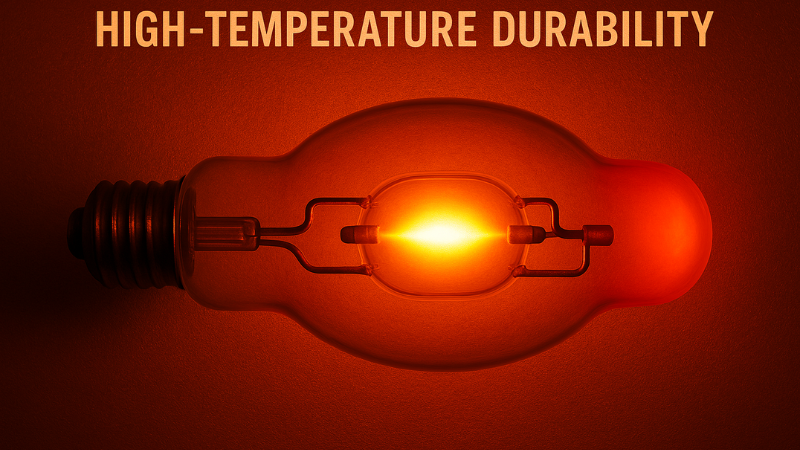

Metal Halide light lamp materials make them durable and efficient, with properties such as heat resistance, protection against UV radiation, and high-temperature endurance in secure and long-duration applications.

MH lamps operate at very high temperatures; therefore, the used materials must withstand extreme heat without breaking down. They have a good IP rating, which makes them weather-resistant, too.

The arc tube inside can be of ceramic or quartz material with thermal stress-sustaining ability, yet delivering good light output after very extended periods of time. The external bulb, typically borosilicate glass, offers shock, temperature fluctuation, and physical pressure resistance.

Because MH lamps release ultraviolet radiation, a UV-blocking coating on the outer layer of the bulb is incorporated into most models.

This prevents hazardous UV radiation from permeating through and harming surrounding material close to the lamp, thereby lessening health hazards, particularly indoors.

All parts are selected because they are heat-resistant for a prolonged period of time. What this implies is that the lamp is longer lasting and safer, even in industrial or open-place usage where longevity is an issue.

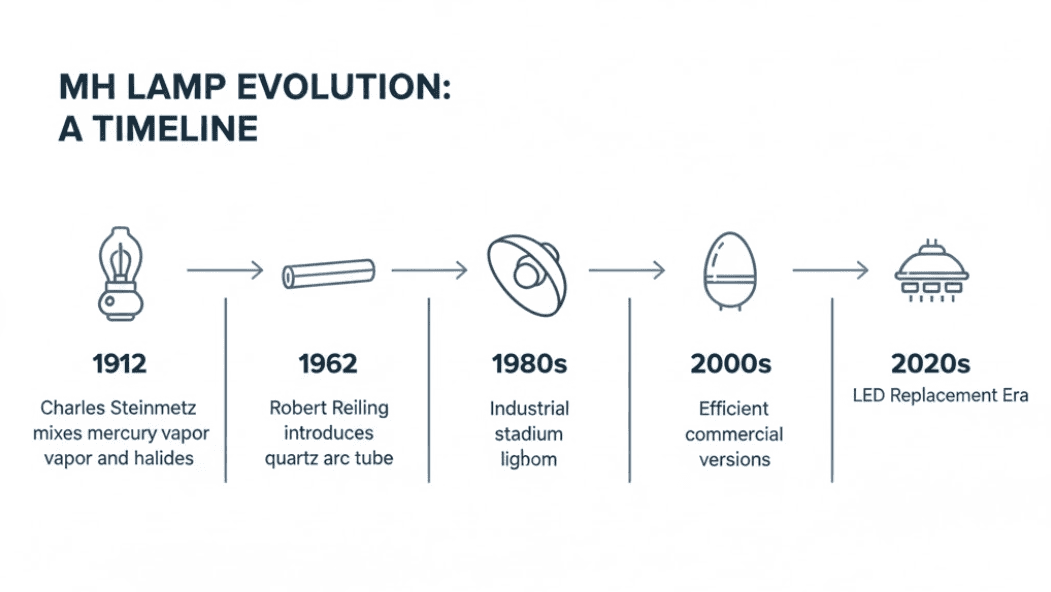

The history of Metal Halide lamps developed out of initial experimentation with a globally utilized method of lighting due to improvements in manufacturing processes and material technology.

Metal Halide lamps originated from early lighting experimentation where mercury vapor was mixed with halide salts. It was during the year 1912 that Charles P. Steinmetz found that brightness was improved with salts.

The turning point occurred in 1962 when Robert Reiling used a quartz arc tube, which removed durability issues and improved performance.

Initially expensive and used for particular purposes, MH lamps became cost-effective as manufacturing processes improved. In the 2000s, they were used widely along roads, sports stadiums, and business areas for efficiency and intense illumination.

Metal halide lamps have a number of applications in various ways, including longevity, good emission of light, and higher energy efficiency.

MH lamps work both indoors and outdoors in harsh conditions. They are extensively applied in:

With a lifespan of 15,000–20,000 hours, MH lamps’ lives last many times longer than incandescent bulbs, minimizing maintenance and replacement expenses.

Regarded for brightness and color accuracy, MH lamps project white light and greater luminous flux, which proves optimal for operations that require detailed usage, such as sports fields and showrooms.

They also have a warm white light color temperature that is very close to natural white light. This type of color temperature provides very good visibility.

Energy efficiency is calculated through the lumens-to-watt ratio. Metal halide lamps return more lumens per watt of power compared to halogen or incandescent lighting, helping firms save power without sacrificing lighting.

Metal Halide lamps are gas discharge lamps. Therefore, they have disadvantages, such as warm-up and cool-down periods, arc tube burnout, color shift, UV radiation, and infrared radiation/mercury hazard.

MH lamps require 1–15 minutes to come up to working intensity and also require 5–10 minutes for cool-down when turned off, interrupting activities.

The arc tube would also degrade and burst after a time interval due to a higher current flow rate, which would cause safety concerns and different performance.

Older MH lamps start to shift colors in rare cases, i.e., they turn yellow or pale in color, degrading image quality in important applications.

MH lamps are UV light sources and contain mercury. Both should be disposed of and stored correctly to prevent environmental and health hazards.

Alternatives to Metal Halide lamps are fluorescent, CFL, and LEDs, each of which has some advantages. Based on their use, each one provides various advantages.

Fluorescents and CFL lights are utilized as low-energy replacements in low- to mid-output applications. They are instant on and value for money.

They cannot be utilized for high or cold applications, though. They are meant for low space volume and, therefore, require a quantity equal to one solitary MH lamp output.

LEDs are replacing halogen, CFL, and fluorescent bulbs and are currently the highest energy-efficient replacement for MH lamps. Their advantages are:

So search LED vs Halogen vs CFL vs Metal halide before purchase. Though LEDs are more expensive to purchase initially, their long-term cost savings and return on investment provide strong incentives to companies that value efficiency and sustainability.

| Feature | Metal Halide Lamps (MH) | Fluorescent Lamps | CFL (Compact Fluorescent Lamps) | LED Lamps |

|---|---|---|---|---|

| Brightness | High | Medium | Medium | High |

| Energy Efficiency | Moderate | High | High | Very High |

| Lifespan | 15,000-20,000 hours | 7,000-15,000 hours | 10,000-15,000 hours | 25,000-50,000 hours |

| Warm-Up Time | 1-15 minutes | Instant | Instant | Instant |

| Cool-Down Time | 5-10 minutes | None | None | None |

| Color Quality | Good (High CRI) | Moderate | Moderate | Excellent (High CRI) |

| UV Emission | Yes | Yes | Yes | No |

| Mercury Content | Yes | Yes | Yes | No |

| Cost (Upfront) | High | Low | Low | High |

LEDs are well-suited for companies that desire to save on energy expenses, need excellent system efficiency, minimize maintenance, and exhibit a lower profile. They will perform in almost any setting, even those most traditionally lit by MH lamps.

When the installation cost is too prohibitive or excessive, light must be provided intermittently; MH lamps are still an option. So weigh down LED vs metal halide lamps before choosing your option.

Metal Halide lamps are still an excellent source of light for those applications that demand high-intensity light on a huge scale. Their high-intensity output, color rendition, and longevity make them appropriate for stadium lighting, road lighting, and in industry as well.

With years of commercial and industrial lighting history as a proven and reliable producer, Risuncorp offers products at the cutting edge of performance and reliability.

Learn about our product selection or get a custom consultation today and discover the ideal lighting for your business.

Comprehensive Lighting Solutions for MRO Wholesalers and Professionals

send your inquiry

Hi, I'm the author of this post, and I have been in this field for more than 15 years. If you want to wholesale lighting fixtures or lighting related product, feel free to ask me any questions.

Learn More >>Download our catalog to view all of our lighting products.

Ready to get started ?

Send Your InquiryOur team will get back to you promptly

please

download

Get notified about new products

Our team will get back to you promptly!

Add your first comment to this post