If you are looking wholesale lighting solutions, click here.

When power fails unexpectedly, emergency lighting systems automatically activate to provide illumination and guide people safely toward exits, especially preventing panic and ensuring safety during critical moments.

In a workplace, hospital, shopping center, or apartment complex, installing sufficient emergency lighting promises protection, reduces response time, and saves lives when they really count.

Emergency lighting is a substitute lighting system that is in use whenever the main source of power is interrupted, and thus maintains essential areas such as means of escape, stairs, and emergency exits illuminated in the event of power disruption or an emergency.

The main motive of emergency lighting is to guide individuals to safety when normal lighting is not available, thus contributing towards life safety and reducing the evacuation risks in instances of power failures or other crises.

In public spaces and workplaces, emergency lighting plays a vital role in rescuing lives and preventing confusion. It enables individuals to navigate through the building safely and proceed toward exits without hysteria.

Emergency lighting systems are required to comply with various regulations and standards that ensure they operate during emergencies. The regulations include emergency light code installation, maintenance, and testing to ensure that emergency lighting systems operate during emergencies.

Regulatory Reform For Fire Safety Order 2005 (RRO) applies to non-domestic premises and necessitates the installation, IP rating, maintenance, and regular testing of emergency lighting.

The RRO must be satisfied that the emergency exits are properly illuminated to provide enough light for safe egress and to maintain the system.

The RRO applies to all kinds of premises, including offices, schools, hospitals, and entertainment venues, and it provides emergency lighting as part of the comprehensive fire safety plan.

Fire Safety Approved Document B is a document that gives life safety codes for safety, including emergency lighting. It ensures that buildings are adequately installed with escape lighting in order to safely evacuate in case of emergencies such as fires or power failures.

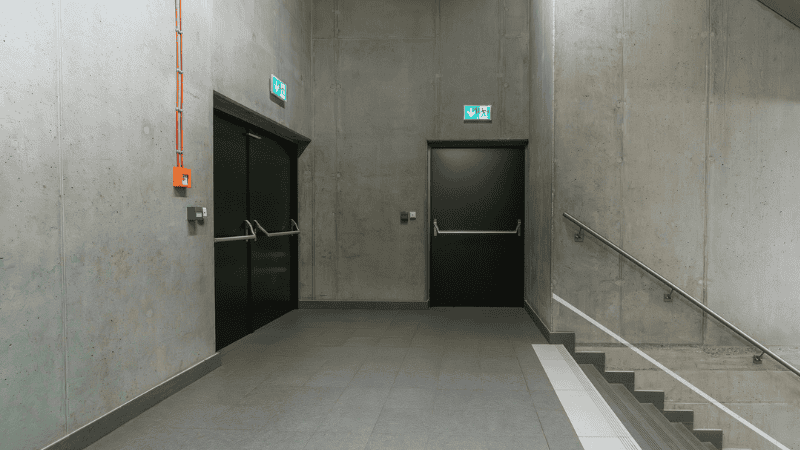

Emergency lighting should be fitted in areas of great importance, such as escape routes and staircases, in order for the inhabitants to move safely.

Compliance with standards like BS 5266-1 (Emergency Lighting Code of Practice) and BS 5499-4 (Escape Route Signing) ensures that emergency lighting inverters are safe and uniform in illumination.

BS 5266-1 addresses the design, Color rendering index, installation, and maintenance of emergency lights. The standard stipulates the lux requirements in various places, such as means of escape (1 lux) and open spaces (0.5 lux).

It also stipulates the emergency lighting duration requirement in a way that emergency lighting shall be in operation for a duration of not less than three hours.

The standard dictates where lighting shall be installed, for instance, means of escape, stairs, and exits, and demands it to be inspected on a regular basis by means of monthly functional testing and yearly full-duration testing for the sole purpose of ensuring reliability during emergency operation.

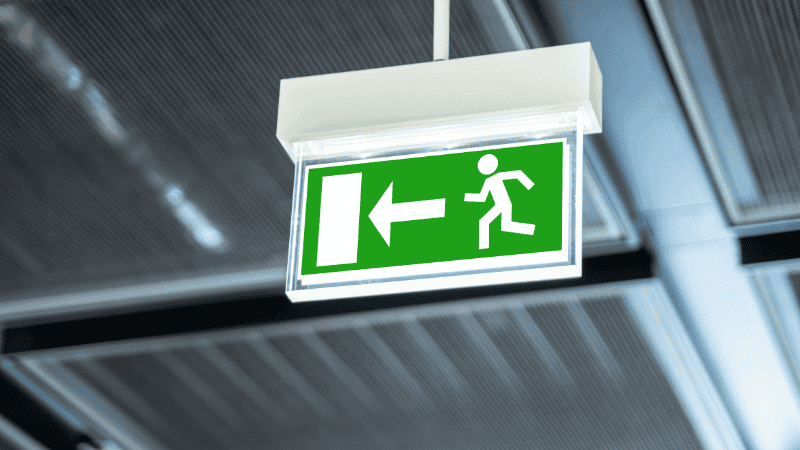

BS 5499-4 prescribes the escape route signs’ location and position to be easily read and visible in diminished visibility. The regulation mandates legible-to-read emergency exit signs readable from appropriate distances.

It also mandates adherence to ISO7010, which has globally accepted safety symbols, so that the building occupants are given adequate time to identify escape routes and escape effectively.

Other standards, like BS EN 60598-2-22 for safety emergency lighting, have performance requirements for installed lights in case of emergencies.

Another very important standard, BS ISO 3864 1, covers safety colors, anti-glare properties, and symbols so that emergency lighting requirements and signs meet international safety standards.

These all help make the emergency lighting facilities functional, safe, and compliant with safety standards, as well as structural to save both the occupants and the building.

Emergency lighting fixtures are designed to provide light during a failure in the normal source of power to allow safe evacuation and continued operation in essential areas. There are various emergency lighting equipment and systems, each with application and operation.

Emergency lighting systems are divided according to their purpose. There are four different types of emergency lighting. They comprise escape lighting, standby lighting, and high-risk task lighting.

Escape Lighting is used to light escape routes and guide people to safety in the event of an emergency. Escape Lighting is usually applied to corridors, staircases, and exits.

Open space lighting is directed at the open spaces so that they can safely leave during low visibility. Lighting of means of escape is used to light the route to the exits.

Standby Lighting is applied to provide necessary operations even in the event of power outages. Standby lighting in places like hospitals, police departments, or data centers keeps necessary areas, like operating rooms or control rooms, lit for necessary activities at all times.

High-Risk Task Lighting is specific lighting for high-risk locations, i.e., industrial or chemical plants, where some tasks can be hazardous without proper lighting. It enables employees to continue their work safely, even in case of a power failure, reducing accidents.

Emergency lighting systems may also be classified according to the mode of operation. They are self-contained emergency lighting and central battery systems.

It is powered by a battery within the lighting device itself. They are simple to install and repair because every unit is self-contained. They are generally used on smaller structures or spaces where centralized power would be impractical.

Central Battery Systems provide alternate emergency lights from a central battery. Central battery systems are typically installed in gigantic buildings or complexes where the maintenance of individual units is impossible.

Central systems would typically be more advantageous for large-scale installation since they allow easier maintenance and testing.

Emergency lighting systems vary based on usage and maintenance frequency:

Maintained Lighting is always on, provided the space is illuminated at all times, even during normal operation. Such lighting is typically installed in spaces where there needs to be constant visibility, like corridors or busy spaces.

Conversely, non-maintained lighting works only in the case of a power failure. Non-maintained lighting is usually installed in places that are not lit throughout the day and night, such as staircases and stores.

Non-maintained lighting will turn on automatically during a power failure to act as a source of light in case of an emergency.

Proper planning and design are required to ensure the smooth operation of emergency lighting systems. System design should consider building layout, occupancy, and code.

A plan for an emergency lighting system starts out with an examination of what the lighting should be in terms of building type, and if it’s an office building, a hospital building, a school building, or another kind of residential or commercial building.

Emergency light installations are regulated by codes, like a minimum lux rating and installation at or near exit paths.

Every building has its own lighting requirements; a workplace has its own lighting requirements; hospitals need critical lighting, while commercial areas need a continuous supply of lighting.

Good design ensures that all the areas have sufficient illumination, such as stairs, corridors, and fire doors, so that people can evacuate the building safely in an emergency.

The need for emergency power equipment also varies with the building type. Public spaces such as malls, shops, airports, or cinema halls need flood lighting for outdoor space safety to accommodate large crowds of people.

Private residences may need lighting for specific areas such as stairs or corridors. Dangerous zones such as factories or laboratories need custom lighting solutions, such as explosion-proof lighting or task-based lighting, to ensure worker safety in the event of potentially dangerous situations.

Emergency lighting systems must also be tested routinely to confirm readiness for use at the time it is needed.

The routine test requirements under the regulation are generally addressed by BS 5266-1 and involve monthly operational testing and full-duration testing on an annual basis.

If emergency lighting works effectively, monthly functional tests must be present on systems to ensure they perform effectively.

The tests ensure the lights switch on and remain on for the required duration. It also checks which types of switches you are using for emergency lighting. There are 8 common types of switches that you can use.

Full-duration annual tests also need to be conducted to simulate a prolonged power cut and to ensure the system operates for the entire specified time, typically three hours.

Also, routine checks and maintenance need to be conducted to detect and correct any faults early so the system remains in working condition at all times.

Self-test emergency lighting systems automatically to ensure they do not work incorrectly. Manual testing is being taken over by self-test systems, and these can provide peace of mind as well as automatically identify failing systems.

Self-test systems possess many benefits, ranging from boosting the confidence level of facility managers and building owners.

Self-test systems are of two types: self-test units and addressable test systems.

They are basic units that run internal diagnostics on each and every light automatically. They usually display their status through the use of LED indicators, whether the unit is functioning properly or needs attention.

These are higher-level. These systems connect every light to a master control board, which monitors the condition of all emergency lighting in the facility. This system is easier to work with, test, and maintain on large installations, providing more details about the status of each device.

Regular maintenance and installation are needed to allow the continued functionality of emergency lighting systems.

In emergency lighting installation, install lights near exit signs, stairs, and corners in an unobstructed manner so that they are visible.

Wiring is also diverse in self-contained and central battery units; hence, proper standards should be employed. Proper installation by qualified individuals, along with regular visual inspection, is required to meet all regulatory requirements.

If your lights are continuously flickering, they are battery drained, have a bulb burnout, or have wiring malfunctions. If none of these is the real cause, then there are some other reasons why your light flickers.

Checks need to be done regularly, batteries replaced at intervals of 3-4 years, and the alignment reset. Any malfunction has to be addressed immediately with repair or replacement to guarantee system operation.

Emergency lighting is very important for the safety of occupants in power loss situations, helping individuals navigate through means of escape and areas of hazard as advised by the National Fire Protection Association.

Installation and testing on standard time frames, like self-test systems, add safety and efficiency and make the system operate when it is most needed.

We strive to provide innovative and high-end light solutions. At Risun Corp, we provide certified, high-performance emergency lighting systems designed for industrial and commercial environments.

Take advantage of a free consultation and learn how we can help you and maximize lighting solutions for your business. Contact us today for a free consultation and discover how to enhance your facility’s safety and efficiency.

Q1: What Cable Can Be Used for Emergency Lighting?

Emergency lighting systems need fire-resistant cables that can endure high temperature ranges and operate uninterruptedly during emergencies, particularly fires.

Q2: Should Emergency Lighting Remain On All the Time?

There are 2 kinds of emergency lighting: maintained (lit permanently) and non-maintained (operates in case of power failure). Maintained provides continuous light, while non-maintained operates on power failure.

Q3: How Do I Test Whether My Emergency Lighting Works?

Emergency lights tend to have an operational green LED indicator. Proper testing, i.e., regular functional testing at monthly intervals and annual full-duration testing, should be done to ensure the system is functioning as required.

Q4: Is Emergency Lighting Compliant in Small Offices?

Yes, there are emergency lighting standards for small offices if they are of complex design or for public use. This ensures the safety of all individuals in case of power supply interruption, as necessitated by BS 5266-1.

Q5: Where Should Emergency Lighting Be Installed?

Emergency lights should be installed in principal locations, such as exit doors, stairs, corridors, and high-hazard areas in hospitals, offices, and warehouses to facilitate evacuation safety.

Q6: What is the minimum lux level for emergency escape lighting?

As per BS 5266-1, escape routes require a minimum of 1 lux, while open areas need 0.5 lux to ensure safe evacuation visibility.

Comprehensive Lighting Solutions for MRO Wholesalers and Professionals

send your inquiry

Hi, I'm the author of this post, and I have been in this field for more than 15 years. If you want to wholesale lighting fixtures or lighting related product, feel free to ask me any questions.

Learn More >>Download our catalog to view all of our lighting products.

Ready to get started ?

Send Your InquiryOur team will get back to you promptly

please

download

Get notified about new products

Our team will get back to you promptly!

Add your first comment to this post