If you are looking wholesale lighting solutions, click here.

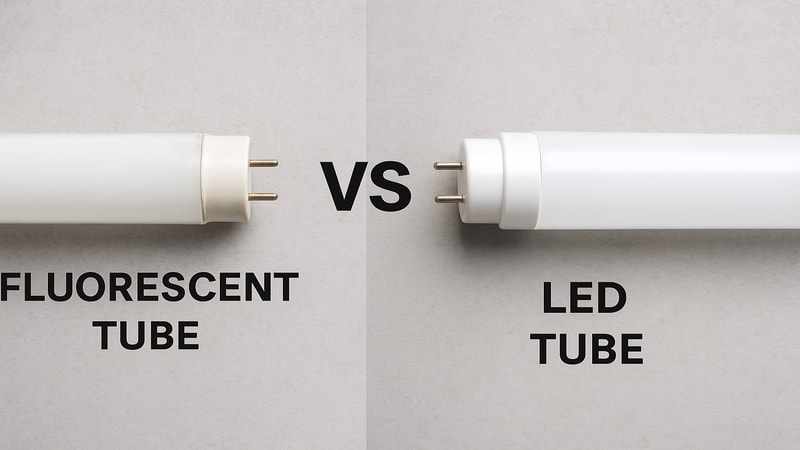

Fluorescent tubes are now being replaced with other options as they consume more energy and have a shorter lifespan. Homeowners and retailers have switched to Type A LED tubes as they are energy-efficient and last longer than alternative lighting sources. This article will help you learn about the benefits and types of tubelights. So read on:

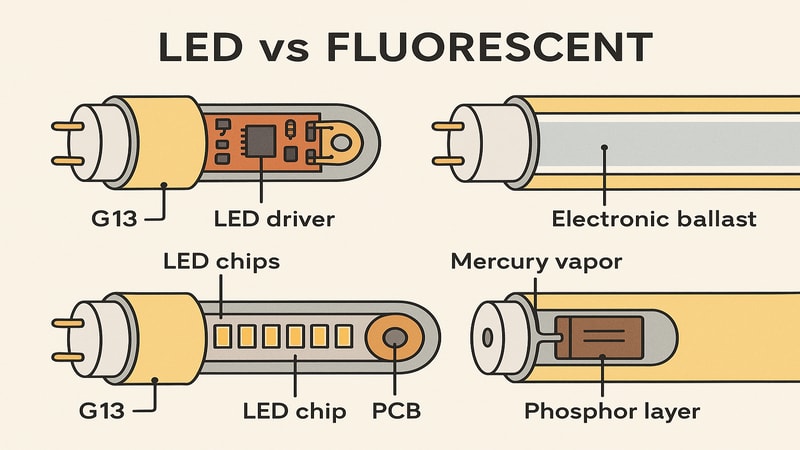

The light-emitting diodes used in LED tube lights are responsible for emitting bright and clean light. Owing to their numerous benefits, they have replaced traditional fluorescent lighting.

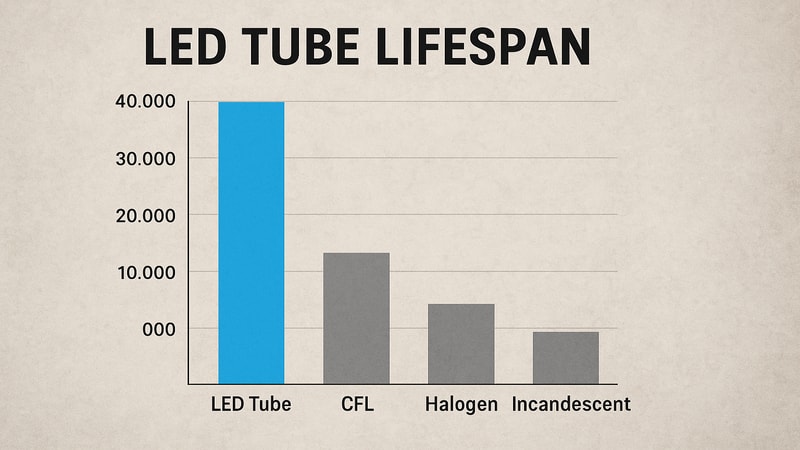

LED tubes are regarded as highly energy-efficient lighting sources because they use 60% less energy than other sources. They can also last up to 50,000 hours, which gives them an advantage over other tubes. Unlike fluorescent tubes, LED lights don’t rely on ballasts or contain toxic mercury.

Also, these lights turn on instantly without flickering. All these benefits make LED lights an excellent choice for business owners. Owing to these features, LED tubes are a common lighting source in offices and other types of commercial real estate properties.

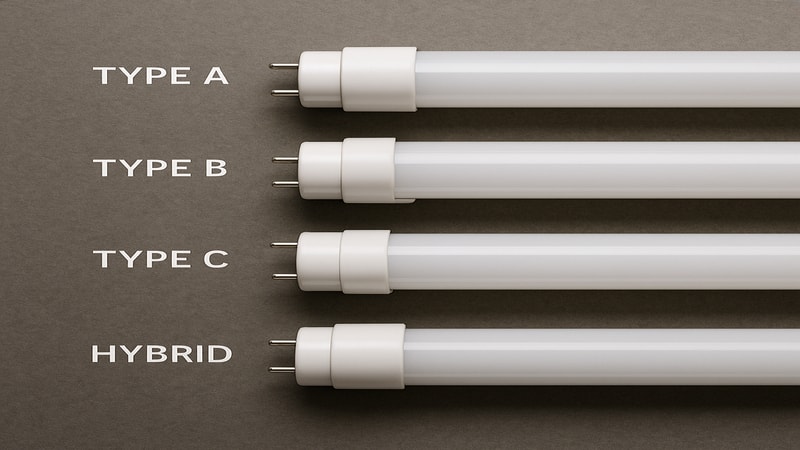

There are multiple types of LED fluorescent replacement tubes; you must choose the one that suits your preference and is compatible with the existing lighting setup.

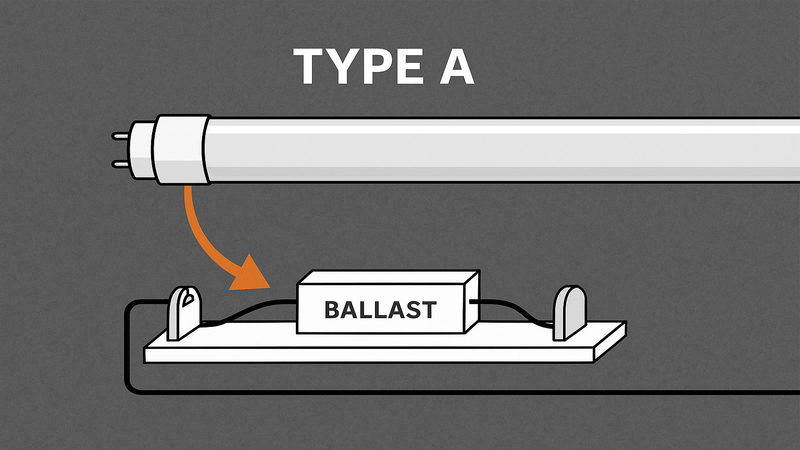

Type A—a simple plug-and-play replacement—is one of the most common tube light types. These LED tubes work directly with the current fluorescent ballast, so no rewiring is needed to connect or install Type A LED tube lights.

The pros of Type A LED tube lights are that they are easy to install and have the lowest downtime. The cons of this type are that ballast compatibility is required, and if the ballast fails, the light will also fail.

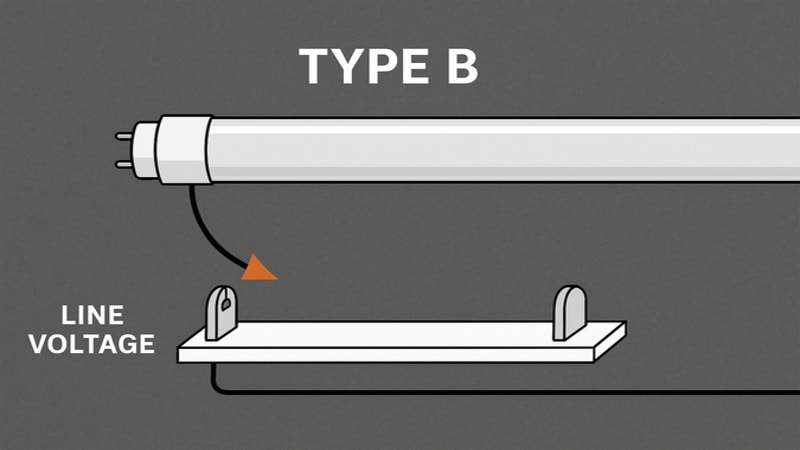

Type B tubes don’t work with a ballast, so one needs to remove the ballast and wire the light to line voltage (L/N).

Since this type doesn’t need a ballast, it is more efficient. Type B LED tube lights have the highest operating hours and don’t need frequent maintenance. However, they require complete rewiring and can only be installed by a qualified electrician.

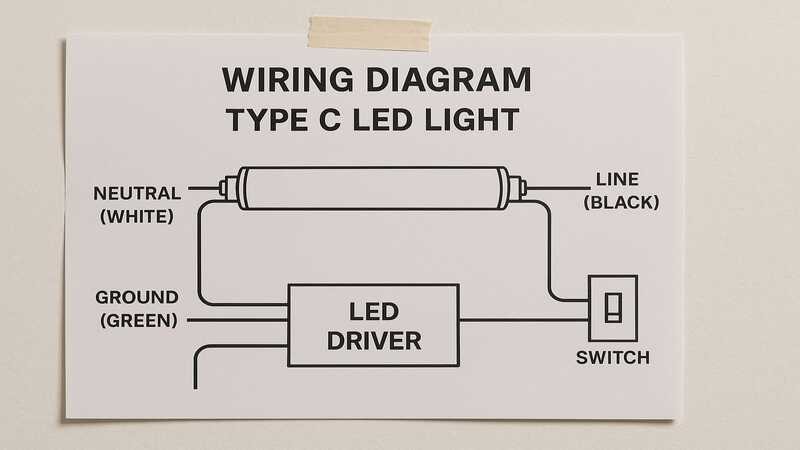

The third type of LED tube light is Type C. Like LED panels and low-voltage lighting, this type uses a separate external LED driver. Type C offers advanced control features, i.e., LED dimming features, which are commonly used in commercial and industrial settings.

The pros of Type C LED tube lights are that they offer dimming features and stable power. However, it is essential to note that this type initially costs more and requires driver installation.

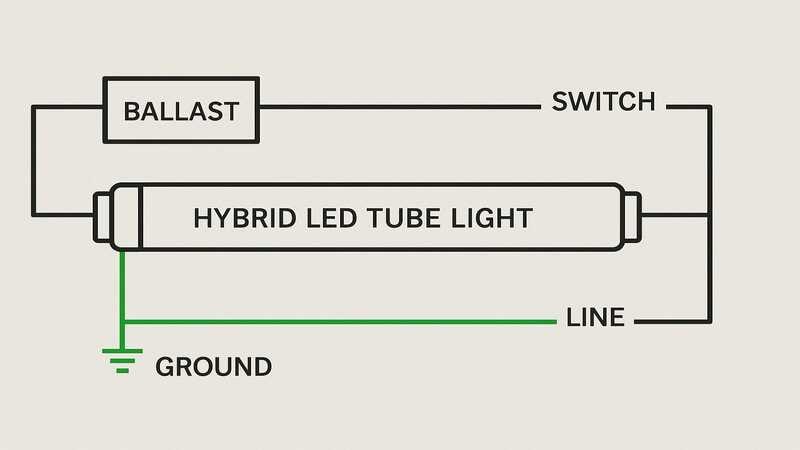

The last type is the hybrid, a mix of Type A and B, i.e., is compatible with a ballast and can be wired directly. This type can be used as Type A initially and as Type B.

The benefits of this type are that it offers higher flexibility and is a one-time investment. However, this type is expensive and does not guarantee compatibility with every ballast type.

Choosing the type of LED replacement for fluorescent tubes is simple but crucial. Procurement managers need to consider several factors to make the right choice. The factors that one needs to consider while selecting the tube are as follows:

Business owners and DIYers must evaluate whether they want to replace the existing fixtures. If not, then Type A is the best choice for you.

Type A is designed to be used with existing ballasts. To install it, you just need to remove the old tube from the fixture and install the Type A. Type A is the easiest and cheapest to install and is commonly used in residential properties.

In case you can replace the fixture, Type B LED tube lights are the best choice. Type B requires you to remove the existing ballast and is more efficient.

Another factor that can help procurement managers decide on the type of LED tube light to choose is whether they want to rewire it.

Type B is ideal if they want to rewire, as it requires removing the ballast and wiring the tube directly to the line voltage. This type is complex to install, but its other benefits outweigh its complexity.

On the other hand, if procurement managers can’t rewire or don’t want to hire someone, they can choose Type A or C LED lights. Type A lights can be installed directly with the ballast, whereas type C requires a separate driver and doesn’t require rewiring.

The budget greatly helps determine the choice of LED light type. If your company has allocated a high budget to the lighting head, you can choose between type B or C LED tube lights. These lights have a higher upfront cost but are reliable and last longer.

Although the initial cost of type B and C tube lights is high, their lower replacement and maintenance costs make them popular.

If you are low on budget or can’t afford to spend much money initially, then Type A LED tube lights are ideal. This tube not only costs less but is also easy to install. You can install it on your own and save on labour costs.

The table below gives a clear view of which type of LED tube light is best for which user and also explains the reason behind this:

| User Type | Best LED Tube Type | Why |

|---|---|---|

| Homeowners | Type A or Hybrid | These types are easy to install, have the lowest upfront cost, and cause minimal disruption. |

| Commercial Retrofits | Hybrid or Type C | Highly energy-efficient and support advanced lighting controls, making them ideal for commercial settings. |

| New Constructions | Type B or Type C | Their high energy efficiency makes them the best choice for newly constructed buildings. |

| Budget-Conscious Users | Type A and Type B | Type A saves on installation costs with no rewiring, while Type B has no ballast and the lowest power consumption, making both cost-effective. |

Lastly, and most importantly, it is highly recommended that you check the fixture type. LED tube lights are generally designed to replace traditional T8 vs. T12 fluorescent tubes and utilise the G13 bi-pin base, common in 4-foot linear fixtures.

T8 tubes are 1 inch in diameter, while T12 tubes are 1.5 inches in diameter. Most LED tubes are compatible with T8 fixtures, but can also fit T12 fixtures. Hence, evaluating the base type and fixture size is crucial to ensure fit and performance.

Like the features, each type of LED tube light also differs in connection and installation procedure. A step-by-step guide on LED tube installation is given below:

This type of LED light does not require rewiring or installation of the external driver, so it is the easiest to install. All you need to do is follow the following steps:

Installation of Type B tubes includes removing the ballast and wiring the tube to direct voltage; they are complex to install. The step-by-step guide for electric contractors on installing the Type B tube is as follows:

Safety tip: If necessary, use non-shunted tombstones to keep their electrical contacts separate.

To install the Type C LED tube light, follow the steps given below:

Tools used to install LED tube lights include a screwdriver, a voltage tester, a wire stripper, wire cutters, wire connectors or nuts, electrical tape, UL-listed parts, and safety gear.

Procurement managers and retailers must ensure compliance with specific certifications while buying or installing LED tube lights. The standard certifications any LED tube light must comply with include:

Switching from fluorescent to LED tubes offers significant benefits for businesses, both in the long and short term. Below are key advantages that drive homeowners and procurement managers to choose LED tube lights over fluorescent tubes:

Based on the above discussion, it is fair to say that switching from fluorescent tubes to LED tube lights is a great decision. When replacing tubes, careful consideration should be given to the LED light type.

There are four types of LED tube lights, i.e., Type A, Type B, Type C, and Hybrid. All these types have their distinct features, pros, and cons. This article lets you easily determine the type that best fits your lighting requirements.

Evaluate the existing fixture to make an informed decision. Always choose high-quality LED tube lights and install them carefully to avoid problems later on.

Looking for a reliable partner to buy LED fluorescent lights for your business? No need to look further! RisunCorp is here to help you with all your LED tube light requirements, whether you are a procurement manager or retailer.

With 14+ years of experience offering one-stop lighting solutions, we can easily meet your wholesale lighting needs. Contact us and get a quote for your wholesale lighting requirements now.

The answer to this question depends on the type of LED tube you replace the fluorescent tube with. If you are using Type A, you can directly replace it, as Type A LED tubes are compatible with current ballasts.

If you are using Type B (Ballast-Bypass) LEDS, the answer is no, as you need to remove the ballast and rewire Type B LED lights.

You can use LED tube lights in fluorescent fixtures, but certain conditions must be met.

The ballast compatibility must be determined; if the ballast is compatible, then the Type A LED tube lights can be installed in fluorescent fixtures.

Alternatively, you can use Type B LED tube lights with a fluorescent fixture only after eliminating the ballast. Lastly, for Type C, you must install an external, separate LED driver first.

The T8 or T5 is the unique code allocated to fluorescent tubes. The T in this code stands for tubular, which defines the traditional long shape of tube lights.

The numeric digit in the code stands for the tube’s diameter, which is measured in eighths of an inch. For example, a tube with code T8 explains that it is tubular and has a diameter of 8/8 inches = 1 inch = 25.4 mm.

The easiest way to check the ballast type is to check the label on the ballast or inside the light fixture. Another way to determine the type of ballast is by looking at the size of the tube—T8 tubes are 1 inch in diameter, while T12 tubes are 1.5 inches in diameter.

Also, T12 ballasts are magnetic and produce a humming sound, while T8 ballasts are electronic and produce no sound.

Comprehensive Lighting Solutions for MRO Wholesalers and Professionals

send your inquiry

Hi, I'm the author of this post, and I have been in this field for more than 15 years. If you want to wholesale lighting fixtures or lighting related product, feel free to ask me any questions.

Learn More >>Download our catalog to view all of our lighting products.

Ready to get started ?

Send Your InquiryOur team will get back to you promptly

please

download

Get notified about new products

Our team will get back to you promptly!

Add your first comment to this post