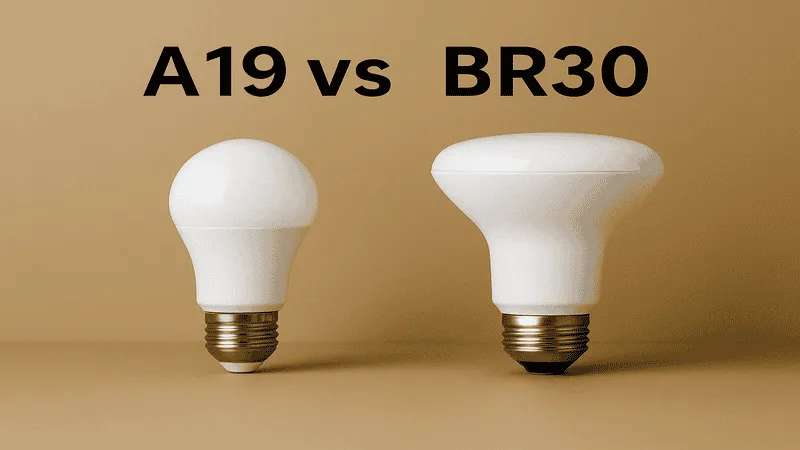

Have you ever encountered the term BR30 on light bulbs or their boxes? Well, you are not alone. Many people know the term BR30 but lack knowledge of what it means.

In simple words, BR30 is a bulb code that explains its size, style, and shape. Read this article to learn what a BR30 light bulb is and why the LED version of this bulb is popular nowadays.

What Does BR30 Mean?

BR30 is a code assigned to a unique type of light bulb. This code helps explain the bulb’s size, type, and shape.

BR stands for bulged reflector, where bulged means rounded and reflector refers to a shiny surface that reflects light inside. Simply put, BR led bulbs are rounded in shape with reflective insides to distribute light evenly.

The numeric part of the code refers to the bulb’s diameter, which is measured in eighths of an inch. A BR30 bulb’s diameter is 30/8 = 3.75 inches.

These bulbs are designed to provide broad and soft lighting distribution, making them ideal for use as a lighting source in homes. Due to their compact size, these bulbs are popularly used in recessed lighting.

The rounded top of this LED bulb acts as a light diffuser, distributing light evenly throughout the area rather than concentrating it in a single spot. Lighting buyers often debate the topic of PAR 30 vs BR 30, and some even consider them the same.

PAR bulbs produce a narrow, focused light beam due to their flatter front and are ideal for spotlighting. Alternatively, BR light bulbs, with their rounded front, make abroad and soft light beam suitable for general lighting.

BR30 Bulb Dimensions and Fitting Guide

Before fitting the BR30 bulb, electricians must know its size and dimensions. BR30 LED bulbs commonly measure 5.1 inches long and have a diameter of 30/8 = 3.75 inches.

Owing to its size, this type of bulb is suitable for most four—to six-inch recessed cans and track lights. The energy efficiency of these LED light bulbs makes them popular for indoor lighting fixtures, especially in residential settings like kitchens, dining rooms, and laundry rooms.

These bulbs come to the rescue in cases where space is limited but a wide and even distribution of light is required. Many people confuse BR30 bulbs with BR40 bulbs or consider them the same.

It is important to note that the difference between these two bulbs is in their sizes. The BR40 bulb is slightly larger, measuring 6.3 inches long and 5 inches wide. A BR40 bulb cannot fit in a can designed for a BR30 bulb.

Quick Tip: Check the label details on the fixture or measure the can size to buy an incandescent light that fits properly and is compatible with the fixture.

BR30 vs BR40 vs PAR30 vs A19: What’s the Difference?

Lighting buyers must compare BR 30 vs 40 vs. PAR30 vs. A19 to choose the bulb that matches their requirements. The table below provides a detailed comparison of shape, diameter, beam angle, and the best use of each bulb.

The following table should help interior stylists and DIYers choose the correct bulb for their residential or commercial lighting fixtures.

| Bulb Type | Diameter | Shape | Beam Angle | Best For |

|---|---|---|---|---|

| BR30 | Around 3.75 inches | Bulged or rounded | Wide approximately 120° | Use in Recessed ceiling lights |

| BR40 | Around 5 inches | More bulb-shaped or rounded as compared to BR30 LED lamps | Wide | Bigger and wider ceiling fixtures |

| PAR30 | 3.75 inches | Narrow, Flat, or Parabolic | Narrow around 40° to 60° | For Accent and task lighting |

| A19 | Approx 2.375 inches | Typical round bulb shape | 360° - Omnidirectional | Best for use in lamps and table lights |

The side-by-side comparison above helps business owners and retailers choose the correct bulb. However, if you’re still confused, then each bulb breakdown is provided below for further ease:

1. BR30 (Bulged Reflector 30):

BR30 LED bulbs deliver an expansive beam that softly illuminates the space where they are installed. Their dimensions and size make them famous in kitchens, bedrooms, and hallways.

2. BR40 (Bulged Reflector 40):

BR40 is the bigger version of the BR30 LED bulbs. Both bulbs are the same shape, but their sizes differ. The BR40 diameter is calculated as 40 ÷ 8 = 5 inches. If you need a wide light shaft and soft light output, and your light fixture is spacious, then BR40 is your go-to bulb option.

3. PAR30 (Parabolic Aluminised Reflector 30):

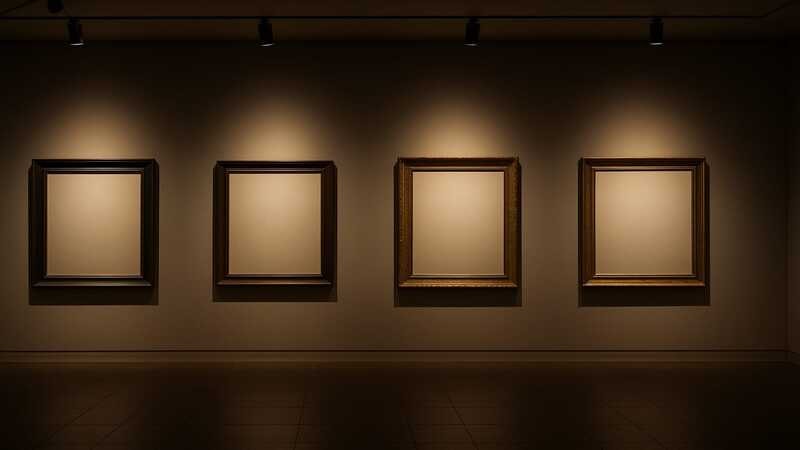

PAR bulbs are concentrated, while BR bulbs are more diffused. PAR30 is used to highlight artwork or display products, as it delivers a very concentrated beam and is ideal for spotlighting. These bulbs have the same diameter as BR30, but the light pattern and beam path distinguish them.

4. A19 (Standard Household Bulb):

The A19 bulb is the most common bulb used in households. It is often seen in table lamps, floor lamps, decorative lighting, and general lighting sources.

When comparing BR30 vs. A19 for residential usages, A19 is the favored choice. It spreads light evenly in all directions and is narrower than all the above bulb options.

When and Where to Use BR30 Bulbs

BR bulbs are typically used in indoor lighting fixtures, especially in places that use recessed or can lighting fixtures.

These bulbs provide a wide beam followed by uniform and brightly distributed illumination. Owing to these benefits, they have particularly replaced other fluorescent light bulbs.

Even with all the advantages of BR30 bulbs, they cannot be used everywhere. Below are some places where you should prefer and avoid BR30 bulbs.

Best Uses for BR30 Bulbs:

BR30 bulbs are commonly used in all types of real estate, including:

- Living Rooms: In living rooms, BR30 bulbs provide warm and smooth lighting that helps with relaxation.

- Kitchens: Selecting the right light is one of the standard rules to follow while designing kitchens. The light source needed in kitchens must have a high color rendering index and be able to distribute light evenly. BR30, fulfilling both these requirements, is thus excellent for use in kitchens.

- Hallways & Entryways: One of the most common tips for designing hallways is ensuring proper light selection. An even and wide distribution of light is needed in hallways, and BR30 bulbs help ensure visibility throughout the entryways.

- Home Offices: BR30 bulbs should be used in home offices to reduce eye fatigue and help concentrate on tasks. These bulbs offer clear and wide coverage without glare, making them ideal for the work setting.

- Commercial Places: BR30 LED bulbs’ capacity to spread uniform light makes them popular in the hospitality and retail sectors.

Where are BR 30 Bulbs Not Advised For Use?

Some of the familiar places where using a BR30 or BR40 bulb is not advised include:

- Desk or Table Lamps: You may have noticed that desk lamps reflect light only on a particular area. Desk lamps help people focus only on the lighted area. As BR30 distributes light all over the place, it becomes tricky to focus, so they are not suggested for use in desk lamps or study tables.

- Spotlight Fixtures: In museums, a specific light is used to help visitors focus on particular artefacts. This type of lighting is referred to as a spotlight. BR 30 bulbs cannot be used with spotlight fixtures as they distribute light all over instead of keeping it focused on a certain point.

If you are considering replacing your old lighting source with BR30 bulbs, note that these bulbs commonly don’t have water or weather resistance.

So, it’s best to install them indoors. A bulb marked water-resistant, outdoor-rated, or wet-rated should only be used for outdoor applications.

Choosing the Right BR30 LED Bulb: 5 Key Features

While choosing the BR30 bulb for your lighting needs, make sure to consider the five key features mentioned below:

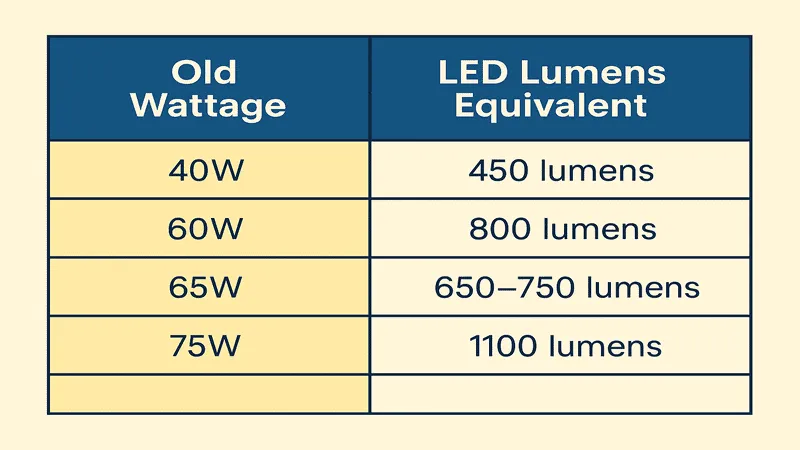

A. Brightness (Lumens)

The brightness of the bulb refers to the visibility of light. Brightness is measured in lumens—the higher the lumens, the more luminous the light. When choosing bulbs, you should not rely only on wattage.

For example, a 65-watt incandescent bulb produces roughly 650–750 lumens in LED form.

LED bulbs consume less energy and can deliver more lumens than incandescent bulbs. So don’t limit your decision to wattage only—analyze lumen ratings to ensure your brightness needs are met.

B. Beam Angle

The standard beam angle of BR30 bulbs is 110–120°. This beam range guarantees enough light for spacious settings.

Lighting buyers should consider the beam range they require before choosing any bulb. DIYers should never install PAR bulbs in BR fixtures, as the narrow beam of PAR bulbs can create uneven lighting distribution or glare.

C. Light Color (Kelvin)

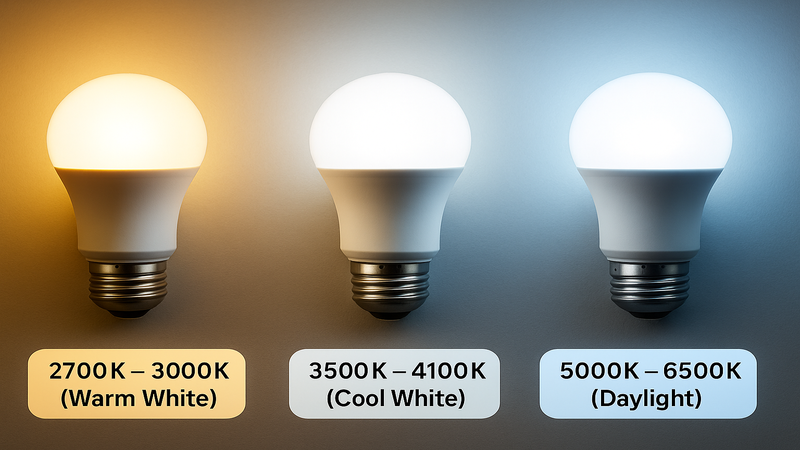

The light color temperature refers to how warm or cool the light appears to human eyes. It should also be considered when purchasing any light bulb. Three light color temperatures are: 2700K = warm white, 3000K = soft white, and 4000 K+ = cool white.

Lighting buyers must choose the perfect color temperature to match their lighting needs. If you are buying a light source for your home, choose 2700K or 3000K bulbs, as 4000K is too bright.

D. CRI (Color Rendering Index)

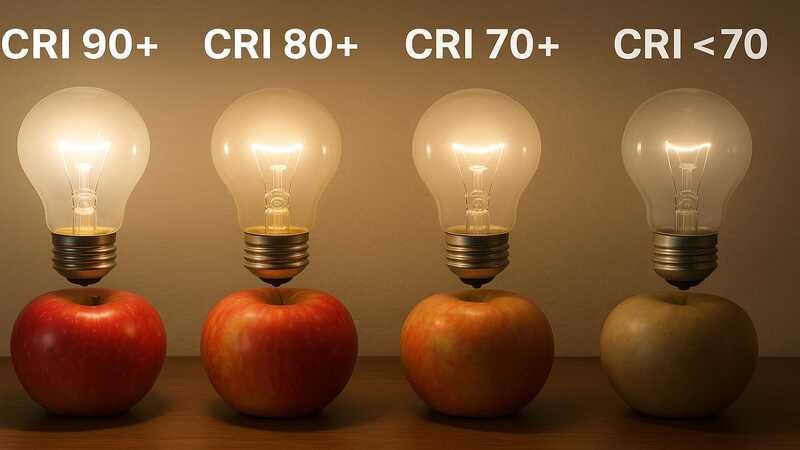

The Color Rendering Index (CRI) refers to how well a light source displays colors compared to natural light. The CRI scale ranges from 0 to 100. A CRI of 90+ is considered perfect, 80+ is regarded as good, and less than 80 is considered poor.

Light bulbs with CRI 80 are ideal for residential use as they use less power and do not contribute to eye strain. When buying a BR30 or any other light bulb, ensure you understand your rating requirements to make the correct choice.

E. Dimmability

The last and most essential feature to consider while buying BR 30 bulbs is the dimmability feature. Not all BR30 LEDs are dimmable; check the label to choose the dimmable light. A non-dimmable BR 30 bulb can cause flickering, so it is not the best light source.

Conclusion

If you are looking for soft indoor lighting for recessed ceiling fixtures in hallways, kitchens, or warehouses, then BR30 LED bulbs are the ideal choice. These bulbs offer a well-distributed beam and efficiently light up any spacious area.

Remember to check bulb specifications like lumens, CRI, colour temperature, and dimming features to make the right choice. Lastly, choose a reliable supplier to get the right bulb for your needs and to save money in the long run.

Partner with Risun Corp for High-Quality Lighting Solutions

The staff at Risun Corp is experienced in efficiently meeting all your lighting needs. With our vast lighting knowledge, we can fulfil all your needs, no matter how unique.

With years of experience in offering one-stop lighting solutions and supplying lighting management for lighting brands, we are sure that we will not disappoint you.

So why waste your time with others? Contact us to place bulk orders for BR30 and other LED bulbs now.

FAQs

Q1. What is BR30 vs BR40?

BR30 and BR40 are typical bulb codes. BR refers to a Bulged reflector, whereas 30 and 40 refer to the bulb’s diameter. Both bulbs are identical in size, but the diameters of these LED bulbs differ. BR40 light bulbs are bigger and broader than BR30 light bulbs.

Q2. Will a BR30 fit a 4-inch recessed light?

A 4-inch recessed light is deemed small for a BR30 light bulb. The BR30 light bulb is around 3.75 inches wide but needs 5 to 6 inches of recessed lighting to fit in. If your recessed light is around 4 inches, the preferred bulb option is BR20.

Q3. Can I use BR30 instead of A19?

You can use a BR30 bulb instead of an A19, but only if the fixture can accommodate the wider bulb. BR30 bulbs are typically used in recessed cans, while A19 bulbs are commonly used in homes for general lighting.

Understanding base sizes makes it easier, safer, and cheaper, whether you’re replacing a dead lightbulb or converting to energy-saving LEDs.

The base is what decides whether the bulb fits at all, although brightness and shape often get the most notice.

This guide to light bulb base sizes will help you make your purchases smarter and frustration-free.

What Is a Light Bulb Base?

The light bulb base is the component that attaches the bulb to the socket so electricity can pass through and energize the bulb, whether it’s for standard lighting fixtures or specialty applications.

The American National Standards Institute (ANSI) has set standardized specifications for the incandescent light bulb bases to facilitate compatibility among manufacturers.

There are two primary types of bases. Though they might appear to be the same at a casual glance, their attachment mechanisms are quite different.

Screw bases employ threading to secure the bulb, while pin bases depend on accurate spacing to line up and lock into place.

- Screw-in (Edison) bases: These twist into the socket and are commonly used in ceiling lights and lamps.

- Pin-type bases: These push or twist and lock into place using metal pins, often found in track lighting systems.

The bulb’s brightness or shape (like A19, BR30) doesn’t determine compatibility. The base is what matters when matching with your fixture.

How to Tell Light Bulb Base Size

Fitting the right lightbulb begins with understanding its base size. However, brightness and shape usually receive the most attention. The base is what determines compatibility with your lamp socket.

The Illuminating Engineering Society provides industry standards for light bulb measurements and documentation.

Using the wrong base size can cause a range of problems, from flickering lights and poor connections to damaged sockets and wasted money.

Whether you’re replacing a bulb or upgrading to energy-efficient lighting, knowing the correct base size helps guarantee a smooth and safe installation.

Understanding both light color temperature and base size ensures optimal lighting in your space.

Check the label on the bulb

Start by checking the label or imprint on your bulb itself—most LED bulbs have their bulb connector type printed directly on the metal or plastic near the bottom. Common codes include E26, GU10, or G9, which tell you the specific base size.

Measure the base manually

If the label is missing or has worn off, install a ruler or digital caliper to take measurements of the base. For screw-in bulbs. Take measurements of the diameter of the threaded part.

For pin bases, take measurements of the distance between the centers of the two pins. This will help you determine the correct size.

Compare it to a base chart

Once you’ve identified the label, check the size of the base. Match your findings with a bulb base size chart. These charts list all the typical bulb connector types and help ensure you pick the right bulb for your lamp socket.

The National Electrical Manufacturers Association reports that the use of standardized base sizes contributes to security as well as compatibility in lighting systems.

Types of Light Bulb Bases

Light bulb bases come in several categories. Each type is designed for specific sockets and applications. Here are the main light bulb size types you’ll come across:

A. Screw Bases (Edison Bases)

These are the most familiar bulb bases for hose upholds. They’re called Edison bases and are set up with the letter “E” followed by a number. The E-series screw bases were developed by Thomas Edison.

The Lighting Research Center states that Edison screw bases are still the most widely used lighting connector in the world.

- E26—The regular base for most bulbs in the U.S. is found in lamps, ceiling lights, and basic lamp sockets.

- E27—Nearly identical to E26 but more common in Europe. Both are typically interchangeable.

- E12—Also called the candelabra base. found in chandeliers. Decorative light fittings and nightlights are examples.

- E17—Known as the intermediate base. Used in microwaves, ceiling fans, and appliance bulbs.

B. Pin Bases (Bi-pin & Twist-and-Lock)

Pin-type bases are popular in space-saving, energy-efficient, and specialty lighting. They don’t screw in—they either push or twist and lock.

- GU10—Common in spotlights and recessed downlights. You insert and twist to lock it.

- G4—A miniature bi-pin base set up in cabinet lighting, desk lamps, and accent lights.

- G9—Loop-style bi-pin base that is simply found in small wall or ceiling lamp sockets.

The Consumer Product Safety Commission advises proper pin alignment in order to eliminate electrical hazards.

C. Specialty Base

- GU24—A twist-lock base found in many energy-saving lamp sockets. Not interchangeable with screw bases.

- B22 (Bayonet)—common in the UK and Australia. The design features a push-and-twist mechanism with locking side pins, similar to some outdoor lighting fixtures.

- S14s, R7s, and BA15d are found in specialty strip lights, floodlights, or older equipment.

Light Bulb Base Sizes Chart

To make identification easier, here’s a quick reference chart showing the most common light bulb base sizes and their typical installs:

| Base Code | Type | Size (mm) | Common Uses |

|---|---|---|---|

| E12 | Screw (candelabra) | 12mm diameter | Chandeliers, string lights |

| E26 | Screw (standard US) | 26mm diameter | Lamps, ceiling lights |

| E27 | Screw (standard EU) | 27mm diameter | Lamps, pendant lights |

| E17 | Screw (intermediate) | 17mm diameter | Microwaves, fans |

| GU10 | Twist-and-lock | 10mm pin spacing | Spotlights, track lighting |

| G4 | Bi-pin | 4mm pin spacing | Cabinet, desk, puck lights |

| G9 | Loop-style bi-pin | 9mm pin spacing | Wall sconces, compact fixtures |

| B22 | Bayonet | 22mm diameter | Fixtures in UK/AUS |

| GU24 | Twist-lock | 24mm pin spacing | CFL, LED fixtures |

| R7s | Linear base | Varies (118mm, etc.) | Floodlights, security lights |

E12, E26, GU10, and Other Popular Base Types Explained

With so many bulb connector types on the market. It’s helpful to know what each code means.

Below are some of the most common base sizes and where you’ll typically find them:

1. E12

The E12 base is a 12mm screw type, with a total bulb height typically ranging from 35 to 50mm. It’s often found in chandeliers, nightlights, and other small decorative lamp sockets where a small size is needed.

2. E26

E26 is the typical screw base in the U.S., and it measures 26 mm in diameter. It is commonly used in most household light fittings, such as ceiling lights, table lamps, and floor lamps. Often referred to as the “medium” base.

3. E27

E27 (27mm) is the European typical. They often fit the same sockets. But you must match voltage ratings to avoid damage or malfunction.

4. GU10

GU10 bases have two short pins spaced 10mm apart, and your bulb locks in place with a twist. These are frequently found in directional lighting.

5. G9

G9 bulbs feature looped bi-pin connectors that push directly into the socket. They are small-sized and often installed where space is limited.

How to Choose the Right Bulb Base for Your Fixture

Choosing the right bulb base doesn’t have to be confusing. As lighting technology improves, compatibility is more important than ever, particularly with smart bulbs, dimmers, and multi-function lighting systems.

The U.S. Department of Energy encourages one to first check compatibility before switching to energy-efficient lighting alternatives.

Tips for Homeowners

It’s also helpful to understand regional differences. For instance, while E26 is typically used in the U.S., E27 is used in Europe. Some imported lamp sockets may require adapters or dual-compatible bulbs.

Likewise, if you’re upgrading to smart bulbs, ensure that they are compatible with your socket and home voltage to prevent any connection issues.

Check the light fitting label

Most light lamps have a label near the socket that specifies the required socket style and maximum wattage, like in enclosed light fixtures.

Match the base code and size

Don’t rely on guesswork. Confirm both the code, like E26 or GU10, and the size in millimeters to ensure a proper fit.

Understand that the bulb shape is separate

Designations like A19, MR16, or BR30 refer to your bulb’s shape. not the socket style. Always verify the base code independently.

Bring the old bulb or a clear photo when purchasing

A visual reference makes it much easier for you or store staff to identify the correct replacement bulb.

Check your lamp socket’s manual or label

Check your lamp socket’s sticker or manual for socket style, voltage, and wattage details. This prevents damage and confirms your bulb fits and functions properly.

Common Mistakes When Choosing Bulbs

Making an incorrect choice in bulb bases is frustrating and even hazardous. According to the Electrical Safety Foundation International, among the leading sources of residential electrical problems is the use of incompatible bulb bases. Here are some common errors and ways to prevent them:

- Getting E12 and E14 mixed up—they look the same, but E12 is 12mm and E14 is 14mm. That 2mm difference makes a difference — they won’t fit correctly in the wrong socket.

- Buying a screw base for a fixture— If your fixture uses a GU10 or G9 pin base, then a screw-type bulb such as E26 will not fit at all.

- Forgetting voltage compatibility— Even though E26 and E27 look similar and often fit each other’s sockets, the voltage may differ, especially if you’re using U.S. vs. European bulbs.

How to Avoid These Mistakes?

- Always measure the base diameter or pin spacing.

- Use the base size chart for reference.

- Check your fixture’s manual or label for base requirements and electrical limits.

Conclusion

Learning how to identify a light bulb’s base size is a simple yet powerful skill that prevents frustration and unnecessary returns, whether you are installing living room lighting or workspace lighting.

Knowing the difference between a common screw base and a specialized pin type helps guarantee that your lighting setup is safe, functional, and efficient. This guide empowers you to pick bulbs with ease when replacing or upgrading them.

Still Unsure About Which Bulb Fits Your Light Fitting?

Let our experts at Risuncorp assist you. We offer a wide selection of lighting products and personalized recommendations tailored to your needs. Visit our website or contact us today for hassle-free lighting solutions!

FAQs

Q1: Can an E27 bulb be put in an E26 socket?

Yes. They’re only 1mm different in diameter and are mostly interchangeable. However, always check the voltage rating and manufacturer’s instructions.

Q2: How do I check whether my bulb is GU10 or G9?

GU10 bulbs have stubby, short pins that twist and lock. G9 bulbs employ loop-type pins that push in straight.

Q3: Are E26 and A19 equal?

No. The E26 is the standard base size, which corresponds to a 26mm screw. The A19 bulb shape is typically round. You can have an A19 bulb with an E26 base.

Q4: Are all E26 bulbs interchangeable?

Yes. All E26 bases will fit E26 sockets. However, always check the wattage, voltage, and bulb type (LED, incandescent, smart bulb) to ensure full compatibility.

Lighting is one of the most important factors in making a space appealing. Yet, lighting should also adhere to stringent safety measures.

UL lighting certifications are vital both in residential and industrial environments. They ensure certain safety standards for lighting products. Want to learn more about what UL is and why wholesalers and professionals should care?

What Does “UL Listed” Mean?

The term UL stands for Underwriters Laboratories, a third-party organization. By testing different types of products, they ensure safety and sustainability standards.

UL-listed products undergo rigorous testing against electrical shock and fire hazards. Any light or product approved by UL can fall under one of the following categories.

- UL listed

- UL recognized

- UL certified

- UL classified

In short, if you see the UL-marked seal on any product, it means the product meets UL’s high safety standards. Furthermore, that product will be free from any risk of fire or danger. The table below covers some common products that can have the UL listing mark.

| Products | Use |

|---|---|

| Downlights | Gives direct light downward, often used in kitchens and staircases |

| Ceiling lights | Mounted directly on the ceiling, best for bedrooms and offices |

| Floodlights | Used to illuminate large areas, such as cricket stadiums and parking lots. |

| Wall sconces | Versatile lighting fixture, mostly used for task lighting or accent lighting. |

| Emergency lights | A battery-powered light designed to activate automatically when regular lighting fails. |

Why Is UL-Listed Lighting Important for Wholesale Projects?

UL-rated lighting is critical in supplying wholesale ventures. It avoids electrical hazards, minimizes fire risks, and guarantees the product’s dependability. Further, it guarantees the correct color temperature and high color rendering index.

Certified equipment prevents mishaps at the office and home, says the Electrical Safety Foundation International.

By increasing trust among customers, it enhances acceptance rates in commercial installations. Eventually, in the buyer’s place, we would also prefer certified products. Some more key points to understand the importance of UL-listed lighting are:

- Market recognition: UL is a widely trusted certification across the U.S., similar to DLC lighting certification. And it is recognized by both consumers and contractors for high-quality products.

- Insurance coverage: UL-listed products, in most cases, are ideal for meeting insurance policy requirements. Because many insurers prefer certified electrical components to reduce risk.

- Cost-effective: Despite a higher front cost, UL-listed lighting can be cost-effective in the long run for wholesalers. It is due to fewer warranty claims and reduced product failures.

- Building codes: Different building codes require lighting fixtures to meet specific safety standards related to electrical safety, which UL certification guarantees.

UL Listing vs. Other Certifications (ETL, CSA, CE)

Apart from UL, there are other certifications like ETL (Electrical Testing Laboratories), CSA (Canadian Standards Association), and CE (Conformité Européenne). These certifications are used to verify that products follow established safety requirements.

Here is the comparison table between UL, ETL, CSA, and CE.

| Certification | Issuing Organization | Region Accepted | Trust Level and Application |

|---|---|---|---|

| UL (Underwriters Laboratories) | Global independent safety science organization | Canada and the U.S. | Highly trusted in the U.S., typically applied in lighting products, home appliances, and safety equipment. |

| ETL (Electrical Testing Laboratories) | Intertek (Global Testing Lab) | Canada and the U.S., and some global markets | A good alternative to UL, highly trusted in the U.S. and Canada, covers lighting fixtures, home appliances, and industrial equipment. |

| CSA (Canadian Standard Association) | CSA group | Canada, widely recognized in the U.S. and some international markets | Highly trusted in Canada, accepted in the United States, and often considered for electrical and gas regulations. |

| CE (Conformite Europeenne) | Self-declared | European Union and European Economic Area | CE marking is a necessity for selling in Europe, but it’s not a safety certification such as UL. CE is used on products such as toys, electronic gadgets, and machinery, among others. |

All certifications are recognized as NRTL (Nationally Recognized Testing Laboratories). Yet, UL is considered the U.S. gold standard due to its high reputation and widespread credibility.

The UL Listing Process for Lighting Manufacturers

The UL listing process is a significant way for lighting manufacturers to certify their products as safe for the U.S. and other nations. The International Electrotechnical Commission provides global standards for functional safety that complement regional certifications.

Underwater Laboratories (UL) is an internationally recognized certification process. And it tests products for arduous standards. The UL listing process for lighting manufacturers is below:

1. Product Design and Documentation

To gain a successful UL certification, you should begin by designing your lighting product according to the relevant UL standard. Ensure you apply UL-recognized components in your original design. Consider the same approach when selecting the right angle for the light beam.

Give UL engineers all information about your product, including documentation. Different types of lighting, like retail store lighting, restaurant lighting, or workplace lighting, have UL standards.

2. Submit Samples

Submit your product samples and technical documentation to UL. They test products against specific safety standards.

3. UL lab testing

In UL lab testing, your product is carefully checked for safety, as well as for electrical, mechanical, and thermal tests.

4. Factory inspection

UL may visit your factory to verify the quality control process of manufacturing. This step will also ensure that only UL-recognized components are being used.

5. Certification and labeling

Last, but not least, your product will receive the UL mark if it meets all requirements. Following this, labeling the product with the UL mark will be mandatory for sale. The UL listing process for your lighting manufacturers will not end here.

Even after approval, UL keeps checking to ensure UL-certified products still meet safety rules. These inspections can range from product testing to unexpected factory audits.

UL Listed vs. UL Recognized vs. UL Classified

UL listed, UL recognized, and UL classified are three categories that Underwriters Laboratories uses to rate products.

- UL Listed: This term is used for complete products. When a product goes through electrical, thermal, and mechanical tests, it is UL-listed. UL-listed products have specific safety and sustainability requirements.

- UL Recognized: The “UL recognized” is used for components only. These parts are approved for use in UL-listed products after testing for mechanical, electrical, and thermal properties.

- UL Classified: A product will be marked as UL classified if it meets specific safety criteria. This classification applies to particular hazards, regulatory codes, or performance under specified conditions.

In addition, the term “UL Rated” is not an official term; it is not recognized by Underwriters Laboratories, and it can confuse users. Be sure to use the correct UL categories. Listed, Recognized, and Classified.

Is UL Listing Required by Law?

UL certification is optional, so manufacturers don’t have to get it by law. While not for personal items, it’s very important for the safety of electrical equipment in your home.

UL certifications are not necessarily required for all products within the United States. However, it commonly requires the use of local codes, insurance policies, and public contracts.

UL certification is also important for stores that sell products. Products like electrical devices or those with lithium-ion batteries. It shields the retailer against liability for the product that causes harm.

According to Energy Star, certified lighting products must meet both safety and energy efficiency standards. Products that are used in the workplace require testing by an NRTL or UL certification.

Here are the products that need to be UL certified.

- Electric appliances (heaters, fans, cooking appliances, animal care appliances)

- Lawn mowers

- Leaf blowers

- Electronics (television, smartphones, tablets, speakers).

Besides home applications, there are areas such as airport runway lights or explosion-proof lights for paint booths. These places require special and stringent certification requirements.

UL certification may not be legally required. But using non-certified products may expose businesses to legal risks or project rejection. Many large companies focus on buying products that have passed UL’s safety test. Also, it will be easy for customers to trust the product if it’s UL certified.

How to Identify Genuine UL Listed Light Fixtures

It is essential to know actual UL-listed light fixtures so that one can buy a secure and dependable product.

Check out the following details to recognize a real UL mark.

- In a genuine UL-listed light, you will see a UL logo in a circle. The UL symbol should be clean with proper spacing.

- The word “Listed” can be shown below the logo.

- A four-digit number on a logo is also key to identifying the product certification with UL.

- The logo printing will be high quality, not faded or smudged.

With this, you can easily recognize real UL-listed light fixtures. However, you should also know how to point out fake UL mark traits. Different lighting products will display UL marks differently. This includes recessed lighting, track lighting, or high bay lighting.

The tips below will help you spot misleading labels.

- There will be spelling errors

- Stretched or blurry logos

- Incorrect font and logo shape

- Last but not least, a “UL Rated” term instead of UL marked or UL recognized

Be sure to purchase light fixtures from trusted wholesalers or brands to get a genuinely UL-certified product. Also, avoid buying low-priced items from unknown sellers, as these often signal counterfeit products.

Benefits of UL Listed Lights for Wholesale Projects

There are several benefits of UL-listed lights for wholesale projects. Such as faster project approvals, lower liability risks, boosted buyer confidence, and higher resale or property value.

- Faster project approvals: If the lights have a UL-listed seal, obtaining project approvals will be easier and faster. UL certification also helps streamline approvals with code officials and building officials. And it is especially important for specialized installations like warehouse lighting or classroom lighting.

- Lower liability risks: Using UL-listed lights can minimize the risk of safety hazards and electrical failures. It will also help avoid insurance denials or costly lawsuits.

- Boosted buyer confidence: When buyers hear that the product is UL marked, they feel confident knowing it has passed all safety testing. This builds trust regarding products among buyers.

- Higher resale or property value: A project that features UL-certified products will always appeal to future investors and buyers. Additionally, the UL certification will also be beneficial for improving your property value.

UL Standards: How They Are Created and Applied

UL standards are created through a collaborative process. It involves expert stakeholders from the lighting industry and government, as well as UL’s standards and engagement team.

Due to this collaborative work, the standards of UL are comprehensive and aligned with evolving performance and safety.

If we talk about UL’s standards categories, there is a wide range that includes

- Lightings

- Electronic devices

- Wiring

- Industrial equipment

- Household appliances

One example of a UL standard is UL 1598, which is generally used for safety requirements for luminaires. It covers aspects like fire hazards, mechanical integrity, and electrical safety.

UL Listing Costs and Timeline

The UL listing costs may vary between $5000 and $50000, depending on the product type, industry, and the scale of certification. The certification fees include a product test fee, a UL marking fee, a follow-up service fee, and miscellaneous fees.

It may take four to sixteen weeks to get UL certification for the product, subject to its complexity. During this process, they check if your documents are complete and if you need to redesign or retest anything.

Manufacturers and wholesalers should budget and plan for UL certification. UL certification expenses should also be considered. You must also consider energy efficiency and IP rating requirements when making new products.

It consists of several important areas, such as inventory management, demand understanding, and resource optimization. For the manufacturer, it will be important not to forget about production planning also.

While wholesalers need to be conscious of sales strategies and inventory management.

Conclusion

UL-listed lighting products are the gold standard for safety, compliance, and market trust. There couldn’t be a better choice for wholesalers than using UL-listed products. It will protect their clients, boost product reputation, and reduce project risks.

By prioritizing UL certification, you show your commitment to quality and reliability. Also, building trustworthy relations and long-term success in the market.

Ready to Prioritize Safety and Trust in Your Lighting Products?

Investing in Risuncorp’s UL-listed lighting is a wise investment for wholesalers and manufacturers. Make sure that your products pass high safety standards, protect your clients, and create a competitive edge in the market.

If you want to enjoy faster approvals and reduced liability risks. Then you must start integrating Risuncorp’s UL-listed lighting into your wholesale projects.

FAQs

Q1: What’s the difference between UL Listed and UL Recognized?

UL Listed applies to complete products that are tested and certified, such as circuit breakers, appliances, etc.

UL Recognized applies to components that can be used inside a product, including the wiring harness and LED drivers.

Q2: Can I sell lights in the U.S. without UL certification?

You can sell lighting products without UL certification across the U.S. However, many resellers and project specs might reject uncertified products.

Q3: Is UL certification accepted internationally?

UL is mainly U.S.-focused, as it is widely recognized in the United States but is often accepted in OEM exports and multinational deals.

Q4: Are UL-listed lights more expensive?

UL-certified lights are slightly more expensive than uncertified lights. But they reduce liability, ensure compliance, and boost buyer confidence.

Q5: Does UL only certify lighting products?

Along with lighting, there is a wide range of products that UL certifies. It includes electronics, cables, batteries, and safety gear.

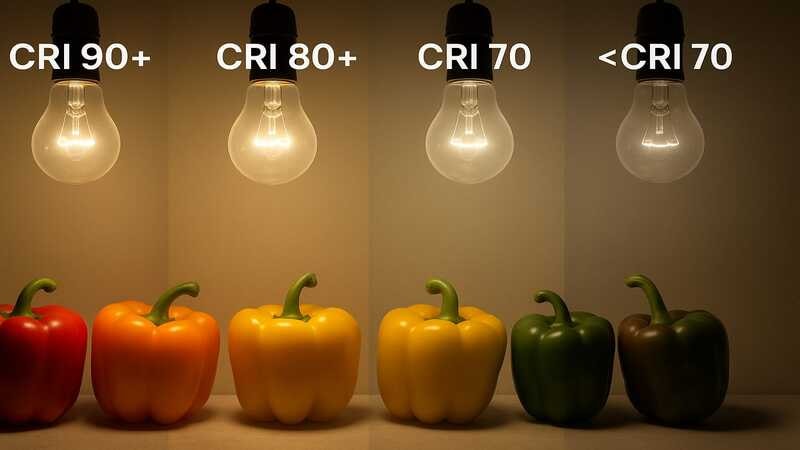

Have you ever noticed that the same products appear different under different lighting? The difference in appearance is due to a term called the color rendering index (CRI).

This article will explain CRI, why it matters, and why designers prefer high-CRI LED Bulbs in commercial fixtures. Read this article to choose the right CRI lighting for your requirements.

What Is CRI and Why Does It Matter?

The color rendering index, commonly known as CRI, measures a light source’s ability to display color as naturally as it appears in sunlight or natural light.

A higher CRI means that the light displays vibrant and natural colors. Similarly, a lower rating indicates that the light source distorts and fades colors.

To better understand CRI, think of it as photo filters. Like filters, some lights fade out or enhance colors, while others display them naturally. Generally, a CRI of above 80 is considered good, while a CRI of 90+ is considered excellent.

Different light sources have varied ratings; you must choose the type that suits your lighting and rating requirements.

CRI Lighting Chart Explained

A breakdown comparison of the CRI scale, along with its best use, is provided in the table below:

| CRI Range | Description | Used in |

|---|---|---|

| 95–100 | Excellent - Display color same as daylight | Studios and Art galleries to capture and display accurate colors |

| 90–94 | Great - Display accurate colors. | Retail stores, hospitals, and makeup studios use lights with this CRI to see accurate colors and perform critical tasks. |

| 80–89 | Good - Most commonly used | Homes, offices, and schools use this index to perform routine tasks easily while preventing eye strain. |

| Below 80 | Poor - Displays colors very differently from natural light. | Warehouses and parking lots use this CRI index as accurate color representation is unnecessary. |

Example Use Cases:

Some uses of each CRI range are given below to make it even easier for you to understand where to use which CRI range:

- CRI 98: Perfect in museums to show the true colours of products, or in dental offices, due to the complexity of dental procedures.

- CRI 92: Perfect for use in a clothing boutique to show the real colors of clothes and avoid customer dissatisfaction.

- CRI 85: Ideal for use in kitchens and living rooms to provide balanced light for conducting the necessary tasks without being too harsh on the eyes.

- CRI 70: A CRI 70 fluorescent tube is mainly used in garages and parking lots to ensure visibility. Modern restaurants also use this CRI level to create a cozy and aesthetic vibe.

Why High CRI Lighting Is Worth It?

As stated, the higher the CRI, the better the lighting. Due to high CRI’s benefits, business owners, decorators, and retailers prefer to buy high-CRI lights in bulk. Mentioned below are some benefits that can be reaped by opting for High CRI Lighting:

1. Proper and Accurate Display of Colors:

High CRI light ensures a natural, vibrant, and accurate display of colors. It is used in retail and fashion stores to make products appear vibrant. Restaurants also use high CRI lights to make the food appear fresh and visually appealing.

The health department also uses high CRI lights to ensure accuracy in diagnosis. High CRI is needed in healthcare as patients may appear paler under low CRI lights. Also, Medications, lab samples, and emergency equipment often use color coding, and a low-CRI light could make a red label look brown.

As CRI acts as a diagnostic tool in healthcare, hospitals install CRI 90+ LED or fluorescent lights for accurate diagnosis. Salons also use High CRI lights in makeup mirrors to analyse skin tone correctly and clearly understand shades.

2. Improved Mood and Productivity:

Lighting significantly impacts human physiology; blue-rich daylight stops the production of sleep hormones and makes the brain active. Similarly, dim and warm lights help your body to relax.

People often use High CRI lighting to uplift their mood and boost productivity. Because high CRI light is close to natural daylight, it helps people stay active, focused, and productive.

Lighting experts and decorators suggest using lights with a high color rendering index in classrooms, gyms, and offices. These highly rated lights help improve productivity and create a refreshed mood.

3. Natural and Comfortable Atmosphere:

Places with high CRI lighting offer a warm and inviting atmosphere compared to areas with lower CRI score lighting.

High CRI lights are generally used in homes, restaurants, and hospitality sectors to create welcoming, natural, and comfortable atmospheres. However, prolonged exposure to any lighting source can strain the eyes, so you need to be careful with the choice of lighting.

Best Places to Use High CRI LED Lighting

High CRI LED lighting is extremely important in places that need an accurate representation of colours. The areas where using a high CRI rating is necessary include:

A. Retail & Showrooms

The selection of light in retail and showrooms impacts sales. If the light source that makes the colors appear faded is used, customers will not be attracted to the products, and hence, the sales figures will be low.

Using high CRI lights in commercial spaces is linked to motivating customers to buy products. Alternatively, a retail or showroom illuminated with warm and inviting light will boost customers’ moods.

B. Medical & Healthcare

You may have noticed that the lights in hospitals are often too bright. This is because an accurate representation of colors is needed for a precise diagnosis.

A maximum rated CRI light is used in the healthcare sector to ensure safety and prevent accidents. Also, doctors must perform medical procedures actively, and a high CRI helps them stay focused.

C. Schools & Offices

High CRI lights are standard indoor lighting fixtures, as they offer ample light to assist with tasks such as reading and writing. Schools are required to install lights with brightness and uniform lighting distribution to improve students’ performance.

Similarly, a high CRI index helps employees focus on work in offices. Low CRI and dim lights also cause eye strain, so they are not advised for use in offices and schools. Due to the high cri benefits, any high CRI-rated light source is an ideal replacement for typical study lamps.

D. Restaurants & Hotels

High color rendering index adds to aesthetics and improves the overall appeal of the setting; thus, they are widely used in hospitality sectors. Interior decorators suggest using high CRI lights as decorative lights in restaurants, as this enhances the dining experience and improves ambience.

Also, people feel welcomed in restaurants with bright, high-CRI lighting, compared to restaurants that have installed low-CRI dim lights.

E. Museums & Galleries

Using high CRI lights in museums and galleries is extremely important. Visitors visit museums to experience products and paintings in their natural form.

High CRI light is vital for preserving artwork and showing it in its actual color. If museums use dim light, visitors will not be able to see the artefacts clearly and will be disappointed.

F. Residential Spaces

Residential properties also use high-CRI LEDS in multiple places due to their numerous benefits. In kitchens, high-CRI lights provide natural light to make the ingredients look vibrant. In wardrobes, high-CRI LED strips are used to see the accurate colors of clothes.

High CRI lights create a soft, aesthetic vibe in living rooms and bedrooms. High CRI lights in homes also help maintain eye health by reducing visual fatigue and strain.

How to Choose High CRI Light Bulbs?

When you are in the market searching for high CRI bulbs, make sure to do your research to buy the correct high Color Rendering Index bulb.

Many types of light bulbs are available in the market, including E12, E26, BR30, and BR40. So, choosing the right one can be tough.

To choose high-CRI light bulbs, you need to consider certain factors. One such factor is to select a bulb labelled as CRI 90+.

A CRI of 90+ ensures that product colors appear as natural as possible. This is ideal for spaces with essential color clarity, like shops, salons, and studios.

You can check the CRI by looking at the box or the bulb specification sheet. Read the sheet or box thoroughly to find the light’s CRI index. Avoid bulbs with a CRI of less than 80 to ensure clear visibility and accurate color representation.

The second thing you need to do is choose the perfect color temperature. Color temperature refers to how cool or warm the light appears to the human eye.

It is measured in Kelvin (K). A light bulb with a color temperature of 2700K–3000K offers warm light and is ideal for bedrooms. A color temperature of 4000K–5000K is average for workspaces, as it provides natural white light.

Always ensure you choose a dimmable lighting source. Bulbs should also be flicker-free. You can check if the bulb is flicker-free by looking at the label or asking the manufacturer. LED lights are flicker-free and dimmable.

They offer a high colour index, consume less energy, and are environmentally friendly, so they are popular in indoor and outdoor lighting fixtures.

Whether buying a high-quality LED light or a high-rated CFI, take the necessary steps to select the right supplier. A reliable supplier will guide you in making the right choice and will be cost-effective in the long run.

Conlusion

Whether you are a homeowner, business owner, or designer, choosing a high CRI-rated light is essential. High CRI rating guarantees better lighting, which is directly linked to better performance.

The high color rendering index tubes and CFLS ensure accurate colour representation and are energy efficient. These lights’ ability to increase work productivity further makes them popular in offices.

So what are you waiting for? Transform your lighting experience by carefully analysing your CRI rating requirement and taking necessary action now.

Partner With Risun Corp For One-Stop Lighting Solutions

Risun Corp is here to help you with all your lighting needs. Our decade-plus experience of providing tailored lighting solutions makes us more reliable.

Our vision of offering cost-effective lighting solutions allows us to provide our clients with reliable, money-saving lighting solutions.

So why waste more time? Get a custom quote for your bulk inquiries by contacting us now.

FAQs

Q1. Are high CRI bulbs worth it?

Yes, High CRI bulbs are worth it, especially in areas that require careful color consideration, like studios, salons, and showrooms.

High CRI bulbs ensure the colors appear as natural as possible and prevent eye fatigue. Compared to low CRI bulbs, these bulbs are expensive, but the benefits justify the high costs.

Q2. What is a good CRI rating for LED lights?

A CRI rating of 90+ is considered suitable for LED lights. This CRI accurately represents colours and is typically used in residential settings.

A CRI of more than 80 is also considered accurate but may not offer enough illumination for some settings. You must consider your lighting requirements to determine a good CRI rating for LED lights.

Q3. Is there a big difference between CRI 80 and 90?

Yes, the difference between CRI 80 and 90 is significant. CRI 90 stands for perfect colour representation, whereas CRI 80 stands for good colour representation. Under CRI 90 lighting, the colours appear vibrant and natural, whereas under CRI 80 lighting, the products’ colour may seem dull.

Q4. Is CRI 70 good?

No, a CRI rated 70 is considered low. CRI 70-rated lights distort colors and are not ideal for indoor settings. A good example of why a CRI 70 rating is not good is that a red apple may appear pale under CRI 70 light.

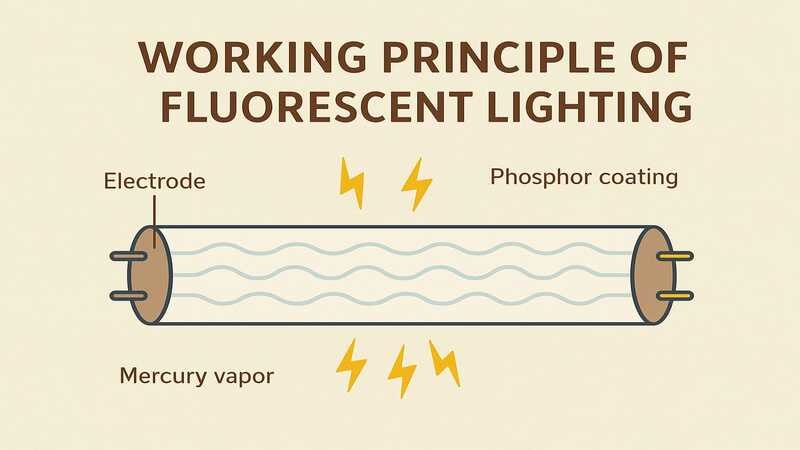

Fluorescent tubes pass current to power mercury vapour, emitting ultraviolet light. The tube then reflects the UV light as bright and visible light. These tubes are commonly used in homes, offices, and other commercial lighting fixtures.

If you want to buy fluorescent lamps or tubes, this article is a must-read, as it explains the fluorescent tube sizes and applications using charts and visuals.

What Are Fluorescent Tubes?

Fluorescent tubes are a common light type in residential and commercial properties. They use mercury vapours and phosphor coating to provide light.

As the electric current flows through the tube, it heats the mercury, emitting ultraviolet radiation. The phosphor coating then converts the UV light to bright and visible light.

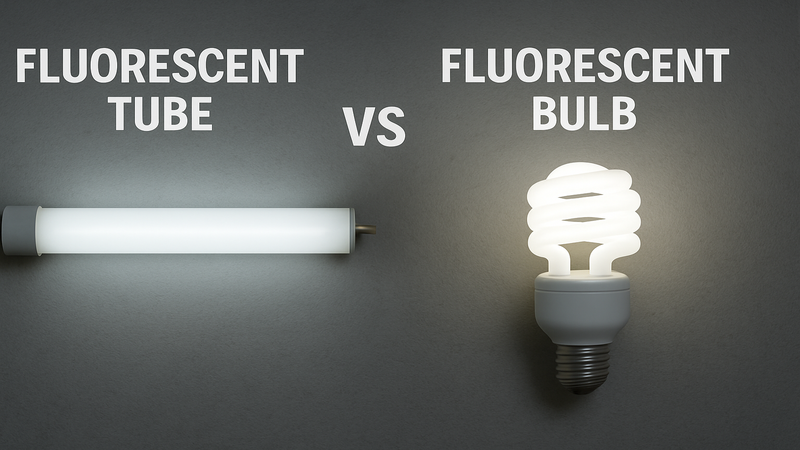

Fluorescent lighting sources are commonly available in two different types. The first is linear fluorescent tubes; these tubes are long and straight. The sleek design makes this tube a perfect under-cabinet lighting source.

The second type is compact fluorescent lamps (CFLs), which are curved and fit in bulb sockets to produce light. These types are equally energy efficient and distribute similar, uniform bright light.

These lights are generally used in office buildings, warehouses, garages, basements, and classrooms—the uniform visible light distribution makes them a popular lighting option.

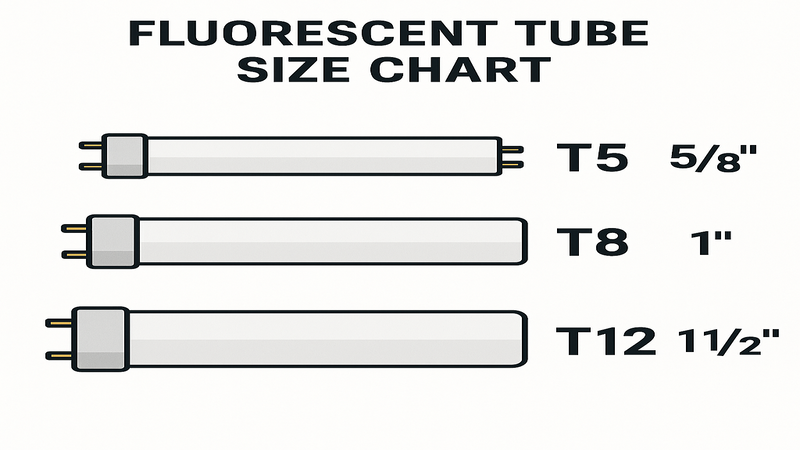

Fluorescent Tube Naming System (T5, T8, T12)

Fluorescent tubes have a unique naming system. Each tube is given a separate code that consists of the letter T followed by a numeric digit. T in the code explains the shape, whereas the digit explains the diameter of the tube.

To further explain, we can say the T stands for the tubular shape of the tube, whereas the digit indicates the tube’s diameter in eighths of an inch.

For example in popular types T5, T8, and T12 the diameter is measured as: T8 = 8 / 8 inch = 1 inch = 25.4 mm, T5 = 5 / 8 inch = 0.625 inch = 15.875 mm, and T12 = 12/8 inch = 1.5 inches = 38.1 mm

The codes help you identify the correct type of tube for your needs. T5 tubes are small and are used when spacing is small or when high light output is required.

T8 tubes are commonly used in schools and residential properties to create a sleek look. T12 tubes are thick and are primarily installed in old settings.

Standard Fluorescent Tube Sizes and Lengths

Fluorescent light tubes vary in length, diameter, and wattage. Procurement managers must determine the type suitable for their applications.

A detailed comparison of different tube types based on their length (both in inches and mm), diameter (both in inches and mm), and wattage is given below:

| Tube Type | Nominal Lengths (in.) | Metric Lengths (mm) | Tube Diameter | Metric Diameter | Power |

|---|---|---|---|---|---|

| T2 | 6",9",12",18",24" | 150 mm, 225 mm, 300 mm, 450 mm, 600 mm | 1/4 inch (≈ 0.25") | 6.35 mm – 7 mm | 6W - 13 W |

| T4 | 6", 12", 18", 24", 36" | 150 mm, 300 mm, 450 mm, 600 mm, 914 mm | 1/2 inch (0.5") | 12 mm | 6W - 20W |

| T5 | 22", 34", 46" | 559 mm, 864 mm, 1170 mm | 5/8 inch (≈ 0.625") | 15.9 mm | 14W – 28W |

| T8 | 18", 24", 36", 48" | 457 mm, 610 mm, 914 mm, 1219 mm | 1 inch | 25.4 mm | 15W – 32W |

| T12 | 18", 24", 36", 48" | 457 mm, 610 mm, 914 mm, 1219 mm | 1.5 inches (1 1/2") | 38.1 mm | 20W – 40W |

How to Identify the Size of a Fluorescent Tube?

Finding the correct fluorescent bulb or tube size is crucial when buying or replacing it. In case you need to identify the size of your current tube, you need to follow the step-by-step procedure outlined as follows:

- Labels are the first thing you need to look at in order to identify the tube’s size.

Tubes and all other lighting sources mostly have printed labels attached to them. These labels help buyers understand the details relevant to tubes like their type, length, and wattage range. You can easily determine your tube size by reading the label. Another option is to ask the manufacturer for the tube specs.

- Secondly, you need to identify the diameter of the tube.

A great option to identify the diameter is by using a caliper or a ruler. To easily figure out the size of a tube, make sure to convert the diameter to eighths of an inch.

- Now that you know the diameter, it’s time to find the length of the tube.

Remove the tube safely from the fixture and measure the length from one end to the other using a ruler or other measuring tool. While measuring the tube, make sure to exclude pins for accuracy.

- Another factor to consider while buying any tube is determining the socket type.

All fluorescent tubes have metal pins at the ends, which connect them to the fixtures. Each tube type has a different pin. For example, the T8 tube uses a G13 configuration, whereas the T5 uses a G5 pin. Thus, knowing the socket type before buying the tube is essential.

By following the steps mentioned above, you can easily find out the size of your tube. Facility managers or electricians need to remember that accuracy in measurement is important, so it’s better to take time to ensure precision.

Fluorescent Bulb Sizes vs. Fluorescent Tube Sizes

The terms fluorescent bulbs and tubes are typically used interchangeably, but they are not the same. Fluorescent bulbs (CFLs) are compact, spiral, or twisted in shape, and fluorescent tubes are long, tabular, or cylindrical.

Tube sizes range from 18 to 48 inches, whereas fluorescent light bulbs are nearly 4 to 6 inches long. Tubes have specific diameters, like T5 = 5/8″ (15.9 mm), T8 = 1″ (25.4 mm), and T12 = 1.5″ (38.1 mm).

However, the diameter of incandescent bulbs varies depending on their shape, but they are mostly smaller than the tube’s diameter.

The labelling of both light sources also differs. Tube light labels are based on the shape and diameter, like T5 and T8. Incandescent bulb labels explain their shape and base, like an E12 bulb and a GU24 bulb.

Both fluorescent tubes and bulbs are energy efficient and provide uniform illumination. Buyers need to determine their needs to choose the one that best suits them.

When buying any lighting source, evaluate your light’s fixture type. If it has a pin connection, you may select a tube; if it has a screw-in socket, you must choose a bulb.

Choosing the Right Fluorescent Tube for Your Fixture

When it comes to replacing fluorescent tubes, electrical buyers and retailers cannot simply choose a tube because it is cheap or because of the amount of light it offers. Whether looking for a fluorescent tube for residential or commercial lighting fixtures, one must consider several factors to make the right choice.

Some of the important factors that influence the choice of a tube are as follows:

1. Compatibility With Fixture:

As discussed previously, the fluorescent lamps come in numerous types. These types vary depending on wattage, size, diameter, and socket configuration.

Each fixture is made for a particular tube type. For example, T5 tubes are used in T5 fixtures, T8 tubes are for T8 fixtures, and T12 tubes are typically used with T12 fixtures. Examining the type of light fixture first and then choosing a compatible tube is vital.

2. Wattage and Brightness:

Before buying a tube, evaluate your fixture’s rating. Different fluorescent lamps have different light outputs and wattage ranges. If the tube’s wattage range is not compatible with the fixture rating, your tube may experience overheating and other issues.

In case a 32-watt T8 tube is replaced with a lower-wattage model, its brightness can be reduced. Similarly, if a 32-watt T8 tube is replaced with a higher-wattage model, the brightness may exceed the light fixture’s safety limit and thus can contribute to common electrical hazards.

Another thing you should know while buying a tube is that the wattage affects light output and energy consumption. So, if you want increased brightness, consider lumens instead of watts.

3. Color Temperature:

Color temperature refers to the appearance of light emitted by the tube. Fluorescent tubes come in multiple options, so homeowners or business owners can choose the color temperature that suits their lighting requirements.

The different temperatures include 2700K—3000K (Warm White), which offers a soft light ideal for residential properties, 3500K—4100K (Cool White), which provides a neutral light ideally used in indoor lighting fixtures, and 5000K—6500K (Daylight), which illuminates blue light best for commercial uses.

The variation in color temperature and high color rendering index allows the lighting buyers to choose the perfect light to improve the overall look.

4. Ballast Compatibility:

A ballast is an essential electrical component of a fluorescent lighting system. It controls the voltage and current supplied to the tube. Ballasts are either magnetic or electronic, and fluorescent tubes are incompatible with all ballast types.

Magnetic Ballasts are older and work well with T12 tubes. Alternatively, electronic ballasts are efficient and work with T5 and T8 tubes. Check with the manufacturer or read the label to determine whether the ballast matches your selected tube.

5. Fluorescent Tube Size Chart (Quick Reference)

This article has already discussed fluorescent tube sizes in detail. For the ease of retailers and electricians, a quick and scannable chart illustrating the fluorescent tube sizes is as follows:

| Overall Size | Tube Diameter | Approximate Length (ft) | Probable Classification |

|---|---|---|---|

| 48 inches | 1 inch | 4 feet | T8 |

| 96 inches | 1.5 inches | 8 feet | T12 |

| 46 inches | 5/8 inch (≈ 0.625") | ~3.8 feet | T5 |

The chart above shows that if your tube diameter is 1″, and is around 4 ft long, the tube type is likely T8.

Quick Tips:

Some quick tips to find out the size of fluorescent lamps or tubes easily are as follows:

- A 48-inch-long and 1-inch-wide tube is most likely to be a T8.

- If the tube is thicker and around 1.5 inches, it is probably a T12.

- The tube that appears slim is T5.

- The thickest tube is the T12 type.

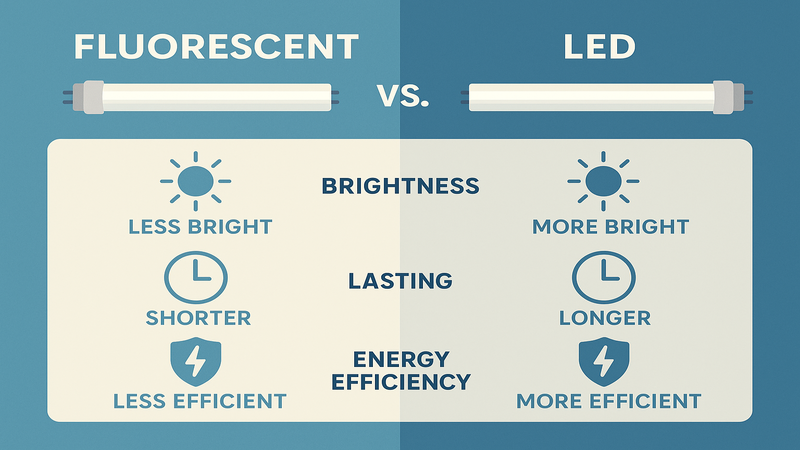

Fluorescent Tubes vs. LED Tubes: Size & Compatibility

One of the common replacements for fluorescent lamps is the LED tubes. LED tubes can be used instead of fluorescent lights directly or by making some modifications. Below is a detailed comparison of the similarities and differences of LED light vs fluorescent tube:

Size Compatibility:

LED tubes and linear fluorescent lamps are mostly the same size; thus, physical dimensions are the same and can be switched easily. A common T8 fluorescent tube is also available in a T8 LED tube, which means you can easily replace a T8 fluorescent light tube with a T8 LED tube or vice versa.

Ballast Compatibility:

When switching from fluorescent to LED tube light, the most important factor to consider is the ballast. Fluorescent lights need a ballast to work safely; however, LED tubes don’t necessarily need a ballast.

There are two types of LED tubes based on how they behave with a ballast. The first type is the Plug-and-play direct replacement. This light works with a ballast and is easy to install, as no rewiring is needed. However, one must check if the ballast is compatible with the tube.

The Second type is the Ballast Bypass (Direct-Wire). This type does not work with ballasts and requires them to be eliminated or bypassed during installation. This type of LED light is difficult to install but consumes less energy, delivers high light output, and needs fewer maintenance and replacement.

Benefits of Switching to LED Tubes:

Fluorescent lamps, bulbs, and lights are great indoor and outdoor lighting fixtures, but they are now being replaced with alternative sources, with LEDs being the most popular.

Fluorescent lamps and tubes consume more energy and use mercury, which is harmful to health. As a result, people are switching to LED tube lights as they consume less energy, are safe for the environment, and last longer than fluorescent lights.

Conclusion

Fluorescent tubes come in different sizes to suit various requirements and are common in industrial and residential settings. To choose the right tube, it is essential to determine its benefits and size.

Due to their benefits, LED lights are now replacing fluorescent lighting sources. Their dimming features make them a popular option for adding aesthetics to settings.

Whether you are buying fluorescent lamps, LEDs, or any other light, make considerable efforts to choose a reliable supplier to enjoy the benefits in the long run.

Risun Corp: Unlock the Best Lighting Solutions For Your Business

With more than a decade of experience, Risun Corp is a reliable partner for all your fluorescent lighting needs. We possess the necessary skills and knowledge to meet customers’ changing lighting demands.

Risun Corp’s ability to offer tailored lighting solutions puts it far ahead of its competitors. Our expert team uses an innovative approach to meet our customers’ unique requirements. With comprehensive market knowledge, we continue to deliver the best lighting solutions.

So what are you waiting for? Contact us today to get a personalised bulk quote for your business.

FAQs

Q1. How do I know what size fluorescent tube I need?

To determine the size of a fluorescent tube, you need to measure the length and diameter of the current tube. The easiest way to determine your desired size is to check the code.

Tube light with code T8 diameter is 1 inch, whereas T12 diameter is 1.5 inches. Standard fluorescent tube lengths are 2, 4, or 8 feet long.

Q2. How do I know if I have T8 or T12?

The simplest way to determine if you have a T8 or T12 tube is by measuring the tube’s diameter. A T8 tube diameter is around 1 inch, whereas a T12 tube is thick and measures 1.5 inches. If your tube is dense, it’s T12; if it is slim, it is T8 or T5. Similarly, you can look at the tube label to determine the type.

Q3. What is the difference between T4 and T5 fluorescent tubes?

T4 and T5 tubes differ in terms of their sizes and uses. T5 tube has a diameter of ⅝ inches, whereas T4 has a smaller diameter of 4/8 inches.

T5 tubes are commonly used in commercial and industrial applications as they offer high light output and lumens, and T4 is a common under-cabinet lighting source.

Q4. Which is better, fluorescent or LED?

Generally speaking, LEDS are a better choice than fluorescent tubes. They consume less energy and last longer than fluorescent tubes. Most importantly, these lights are free from mercury traces and thus are safe for the environment.

The cost of LED lights and lamps is high initially, but the long-term benefits, including fewer replacements and maintenance costs, make them reliable.

Q5. What are fluorescent tubes used for?

Fluorescent lamps are widely used in residential and commercial properties. These tubes offer enough light to assist with conducting tasks efficiently. In offices and schools, fluorescent tubes are low-cost and effective lighting sources.

In warehouses and garages, these tubes ensure even distribution of light. In residential settings, these lights offer ample light while reducing electricity costs.