If you are looking wholesale lighting solutions, click here.

Do you know a simple miscalculation in the selection of the CRI value of lighting design can damage a space’s overall look and feel?

The Color Rendering Index (CRI) is a fundamental concept in lighting design that quantitatively measures the color accuracy of artificial lighting compared to natural light.

In this article, we jump into the complex world of CRI, its benefits, testing procedures, and applications to give you a crash course on everything you need to know about the color rendering index.

The color rendering index (CRI) measures an artificial light source’s ability to faithfully reproduce an object’s colors compared to a natural light source.

CRI is a 1 to 100 rating that is a quick and easy means of understanding the color rendering accuracy of a light source. A CRI of 100 means the objects under an artificial light source look the same as they would under sunlight.

The unit for CRI is often listed as Ra, which stands for R average or the average color rendering capabilities.

The Commission Internationale de l’éclairage (CIE), or International Commission on Illumination, is a century-old institute setting industry standards on light measurement, including the basics of CRI ratings.

CRI ratings serve a simple but useful purpose: represent objects, décor, people, etc., in the best light possible. Accurate reproduction of an object’s appearance is a valuable tool in several industries.

Following is a short list of color-critical industries that showcase the importance of high CRI lighting.

Good lighting design and good photography go hand in hand. The quality of pictures increases exponentially with the quality of the light source.

High CRI lighting can accurately reproduce the true subject colors, especially for subjects’ skin tones. Digital cameras often struggle to capture the natural skin color of people, and high CRI lighting allows photographers to capture more natural-looking images.

Good lighting leads to accurate image recreation in the camera, which leads to more accurate image displays and prints.

Low CRI lights, like fluorescent bulbs, can introduce a slight green or magenta cast to the photos. The color cast becomes a nightmare in post-processing, where an editor has to remove unwanted color hues painstakingly.

A major challenge for art galleries is preserving the vision and intent of the original artist. Paintings from the last 1000 years have used several hundred materials to generate the same vibrant colors.

When artificial light interacts with the ancient paints in these historic paintings, it distills color. Showcasing paintings in natural light is also not an option, as the UV (ultraviolet) radiation from the sun causes fading and distortion.

The only solution to this complex problem is high-quality non-UV LED lighting with a general color rendering index of 90 or above. LEDs are particularly useful here as they are incredibly energy-efficient and have a low heat output.

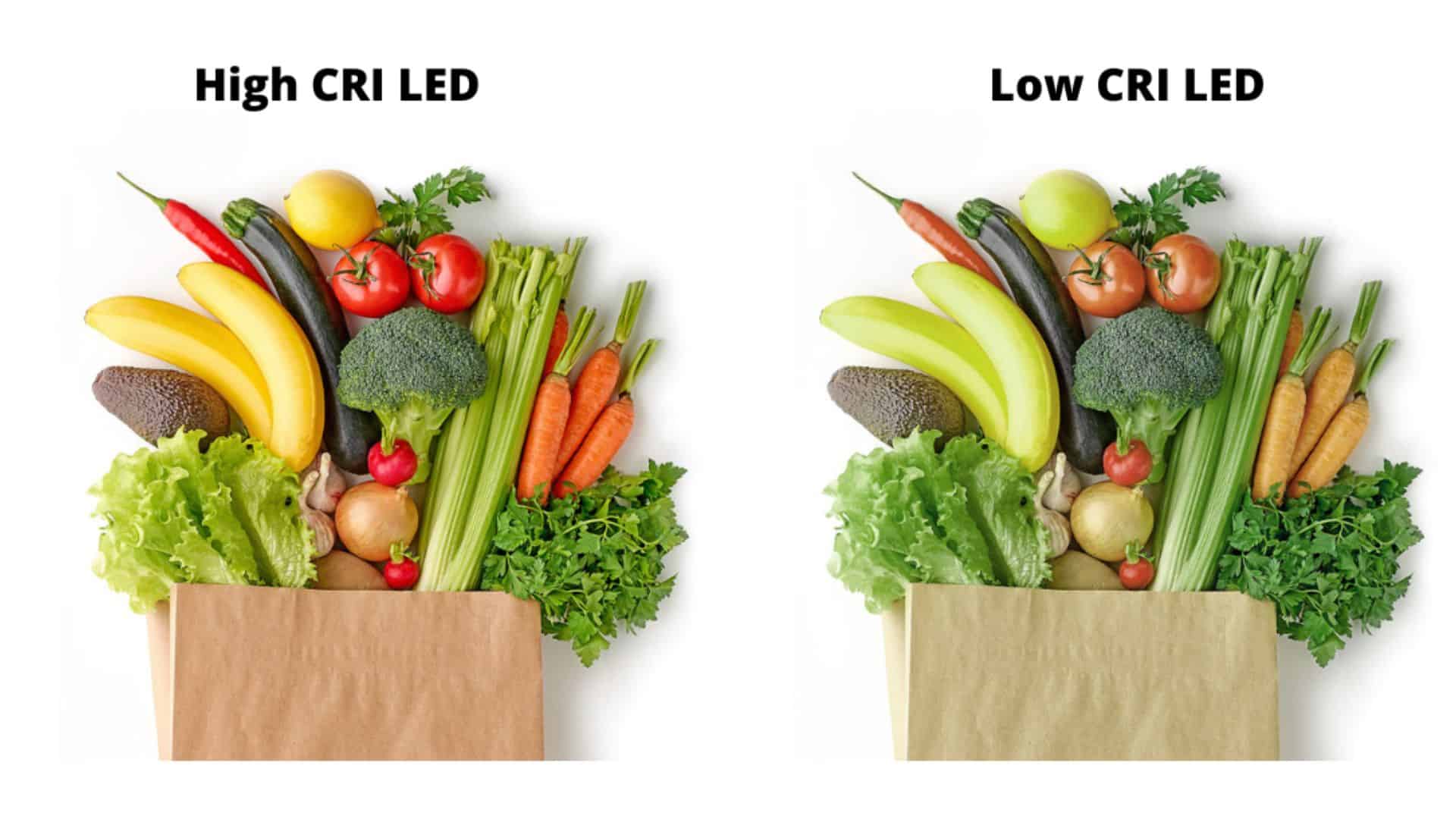

Stores run on the quality of the products and the marketing behind the products. Whether it’s a grocery stand, a clothing boutique, or a furniture store, the products need to shine and look their best.

High CRI light sources make the colors pop. Bright, saturated, and colorful displays attract customers and directly result in sales. The goal of any retail business should be to emphasize the natural colors of its products and enhance its visual appeal.

Quality LED lighting has also been shown to impact the mood and temperament of customers. So, it should be no surprise that businesses prioritizing customers’ visual comfort also see higher sales.

Researching and designing a product is an incredibly challenging process. Perfecting the dimensions, specifications, and product capabilities is already very tough. Add to that accurate color representation, and you have a tremendous task.

A quality product should have a consistent color choice and material finish. Minor visual inconsistencies indicate bad product design and lead to poor brand representation.

A high CRI lets manufacturers maintain consistent color reproduction through multiple batches.

Example: Apple sells tens of millions of iPhones each year. The company must maintain accurate color representation across several factories and vendors for its millions of products.

Using standard CRI (color rendering index) and CCT (color correlated temperature), lighting quality allows Apple to maintain its excellent product quality control.

Finally, the clothing industry is the biggest beneficiary of high-quality lighting. Clothing is all about making a visual statement and being your best self.

The clothing industry relies on good lighting to showcase its products and attract customers. Clothing stores put as much effort into illuminating their products as they do in making them.

While incandescent light sources were common in the old days, they have proven lacking compared to modern LED (light emitting diode) lighting. But LED lighting isn’t limited to clothing stores.

Accurate LED lights are necessary for designing clothes, sourcing fabrics, and testing after-wash changes.

There needs to be a standard illumination measuring system to test the color rendering of fabrics completely. Luckily, the color rendering index (CRI) ratings are just that system.

CRI and CCT are two similar but inherently different lighting quality measurement standards. These terminologies are designed so lighting manufacturers can properly describe and market their products to consumers and serve different market sections.

Measuring a given light source’s color rendering index (CRI) involves a complex testing procedure, a good understanding of the light spectrum, and some advanced mathematics.

Luckily, we have broken down this complex process into simple, easy-to-understand, bite-sized pieces.

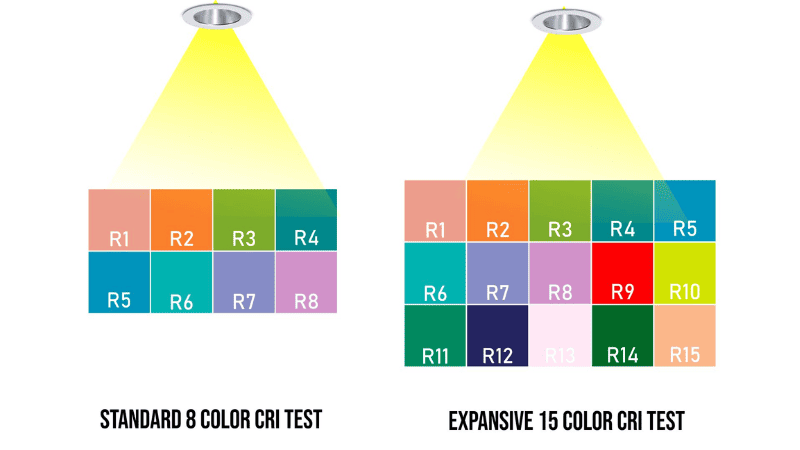

The CRI test uses 8 or 15 standardized test colors, including pastel tones, and saturated and neutral colors. These colors represent a range of hues and saturation levels.

Most color rendering index scores are based on the eight standard color palettes, but an additional 9th color is sometimes included to measure red color recreation.

For more advanced color rendering tests, 15 palettes are used instead. The results of an 8-color test and a 15-color test for the same light source will vary quite a bit.

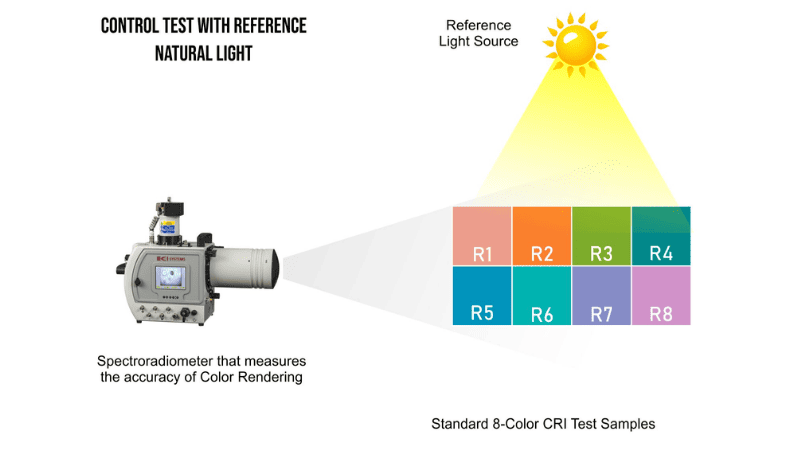

Now that you have selected your set of test colors, 8, 9, or 15, it’s time to run a control test. This basic test will act as a reference for your artificial light source.

A common reference light source is Natural daylight (Daylight Illuminant D65). The test colors are exposed to this light source, and a light measuring tool analyzes the color rendering capability of the light source.

After exposing the test colors to the natural sunlight (or other control light source), a light measuring tool is used to analyze the wavelength and amplitude of the light reflected off of the samples.

Two types of tools are used to measure the color rendering results.

The resultant light emission values are logged into a system for later comparison.

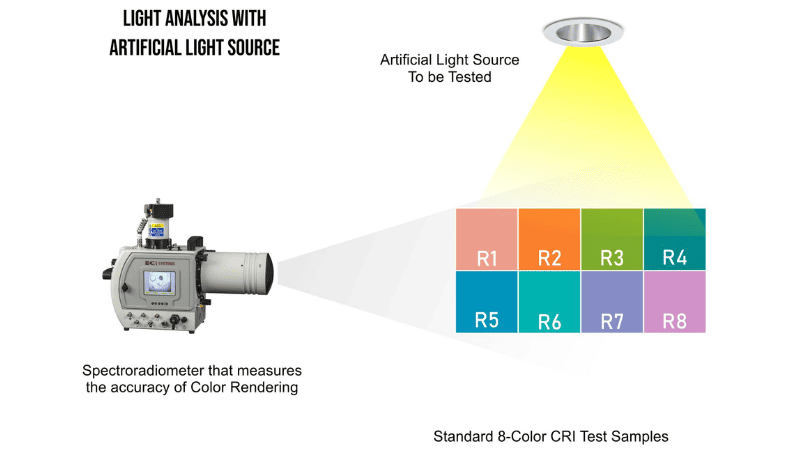

Next, repeat the same testing procedure with your desired artificial lighting. Expose the set of test colors to the artificial light source and measure the results.

The light source should be stable and operate at the manufacturer-rated brightness and color temperature.

Repeat step no. 3, and note down the results of the artificial light source.

Use the visible spectrum data from both light sources and compare the results. The comparison involves plotting color values in a chromaticity coordinate system and matching the artificial light source results with the natural daylight results.

Each of the test colors will be compared individually. If you’re using an 8-color set sample, you will have eight different comparison values, listed from R1 to R8.

Now that we have the comparison results from all eight test colors, we can calculate the average color rendering value Ra.

Ra is the average of all colors, from R1 to R8 (or R15).

Now, we refine all the calculations into one single number on a scale of 0 to 100, with 100 indicating perfect color rendering (i.e., the light source accurately reproduces all colors).

The color rendering index (CRI) is commonly broken down into five categories based on application. Manufacturing high-CRI LED lights is expensive; not all businesses benefit from 90+ CRI fixtures.

| CRI Category | CRI Category | Color Rendering Accuracy | Applications | Details |

| 1A | 90-100 | Excellent | Art Galleries Photo Studios Paint Factories Product Development | Professional Environments where color precision is necessary |

| 1B | 80-89 | Great | Printing Applications Retail Stores Restaurants | Places where good color reproduction is required |

| 2 | 60-79 | Good | Offices, Homes Factory Floors | Places that see improved functionality from good color accuracy |

| 3 | 40-59 | Poor | CCC | Areas that don't benefit from color accuracy. |

| 4 | 20-39 | Terrible | Store Rooms Warehouses, Backup Lights | Places where illumination is all that matters. |

The lowest quality light sources fall under category 4, which comprises fixtures rated 20 to 39 Ra. The second lowest is category 3, with 40-59 Ra fixtures.

Categories 3 and 4 have such poor color rendering capabilities that they can only be deployed in street lamps and warehouses.

Moving ahead, we have category two light fixtures, and these units have an acceptable color rendering score of 60-79 Ra. Anything above 70 Ra is considered good quality lighting. It is the minimum requirement of a residential building that ensures residence comfort.

Next, we have the top two categories, 1A and 1B. For color-sensitive applications, like product marketing and paint manufacturing, 1B is recommended. It ranges from form 80-89 Ra.

Finally, we have the cream of the crop, the highest color rendering index category 1A. It ranges from 90-100 and is the only acceptable light source for professional color-critical applications.

The fashion industry, art galleries, photography studios, and more rely on category 1A light sources for daily business operations.

Manufacturing fixtures with a CRI of less than 20 is practically impossible. Light quality would have to be abysmal for a fixture to get such a low color rendering score. Contrarily, manufacturing 100 CRI light bulbs is comparatively easy.

Let’s look at some specialized commercial applications of high CRI light fixtures.

The aquarium industry might seem small to outsiders, but it is a massive culture involving art, science, and architecture. Lighting an empty room is challenging enough on its own.

Add lots of refractive water, a bunch of underwater decorations, and some photo-sensitive fishes, and your job gets much tougher.

High CRI (Color Rendering Index) lighting plays a critical role in medical imaging applications, where color accuracy and lighting quality contribute to accurate diagnosis, visualization, and patient care.

Following are just some common medical industry applications of high CRI lighting.

High CRI (Color Rendering Index) lighting plays a significant role in factories and other industrial spaces’ safety, productivity, and efficiency.

Following are some common industrial applications that benefit from high CRI lighting.

Here are typical CRI ranges for common light sources, ranging from traditional incandescent lamps to specialized xenon lamps.

| Light Source | Average CRI Range | Average CCT Range |

| Incandescents Bulbs | 90-100 | 2700K - 3000K |

| Halogen Bulbs | 90-100 | 2700K - 3500K |

| Fluorescent Bulbs | 50-95 | 2700K - 6500K |

| LED Lights | 80-95 | 1000K - 10000K |

| Metal Halide Bulbs | 65-95 | 3000K - 10000K |

| Mercury Vapour Lamps | ~20 | 5600K - 6400K |

| Xenon Lamps | 95-100 | 6200K |

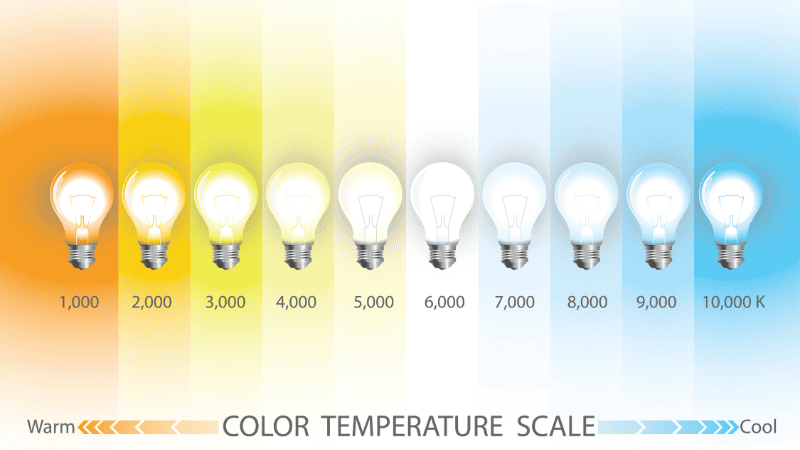

Incandescent and halogen light sources generally average the highest CRI among all light sources. However, these light bulbs are also limited to warm color temperatures, and this has limited applications.

This indicates that while CRI is a good measuring stick for illumination quality, it should be used with other tools like color temperature.

LED lighting has a comparatively lower average CRI. However, lighting manufacturers can use specialized techniques like adding red phosphor to the diodes to increase the CRI to 100.

Again, these minor details show that a color rendering index is more complex than a simple number.

Choosing the right CRI lighting is about identifying your business needs and finding the closest matching lighting source.

Here are three steps that will help you get the best CRI lighting for your workspace.

Quality CRI is necessary for two types of applications.

Now, we know the basic applications that benefit from a high CRI light source. We can talk about hard numbers.

Finally, we have to consider the biggest deciding factor in your budget. High CRI lights are not cheap; going from 80 CRI LED lights to 90 CRI ones is a huge leap in price.

A CRI of 80 means that objects under this light source will have 80% color accuracy compared to natural daylight.

90 CRI light fixtures have 90% of the color rendering accuracy of sunlight. Light fixtures with 80+ CRI are recommended for most commercial applications where color accuracy is needed. Compared, fixtures with 90+ CRI primarily focus on professional applications like photography and art galleries.

CRI is the ability of an artificial light source to mimic the properties of sunlight, while CCT is a measure of the yellow and blue hues present in artificial lighting.

Low CRI lights distort objects’ colors by adding blue or green casts. High CRI lights represent an object’s true colors as if they were under natural daylight.

For most applications, a CRI of 75 or above is recommended. However, a CRI of 85 or above is ideal for color-sensitive professional applications.

The world of CRI is complex and full of technical jargon like color rendition and light spectrum. But once you learn the basics of this lighting standard, the entire process becomes much simpler.

High CRI lighting has several benefits beyond making product displays glow and pop. It helps professionals create even better products and enables businesses to create a more welcoming indoor space.

Risun is all about matching high-quality lighting solutions with esteemed buyers. We aim to deliver cost-effective lighting solutions to our international clients with the best possible customer service. Check out our diverse catalog of indoor and commercial lighting products that cover a broad range of industries and applications.

Your business needs a partner that understands its needs and values its success. Luckily, Risun is just that partner.

Get started on your perfect CRI lighting setup today. Contact us Now!

Comprehensive Lighting Solutions for MRO Wholesalers and Professionals

send your inquiry

Hi, I'm the author of this post, and I have been in this field for more than 15 years. If you want to wholesale lighting fixtures or lighting related product, feel free to ask me any questions.

Learn More >>Download our catalog to view all of our lighting products.

Ready to get started ?

Send Your InquiryOur team will get back to you promptly

please

download

Get notified about new products

Our team will get back to you promptly!

Add your first comment to this post