If you are looking wholesale lighting solutions, click here.

Lighting is crucial in warehouses and large, open spaces for storage or manufacturing purposes. Unlike other indoor environments, warehouses require specific lighting due to their unique characteristics and functions.

But what type of lighting fixtures are best for warehouses? Well, every warehouse has unique energy consumption requirements. However, the most effective solutions are LED lights or fluorescent lights.

Let’s delve into the warehouse lighting guide so businesses can decide when to choose the best lighting for their warehouses.

Due to versatile lighting requirements, different lighting fixtures can be installed in warehouses. Some common types include:

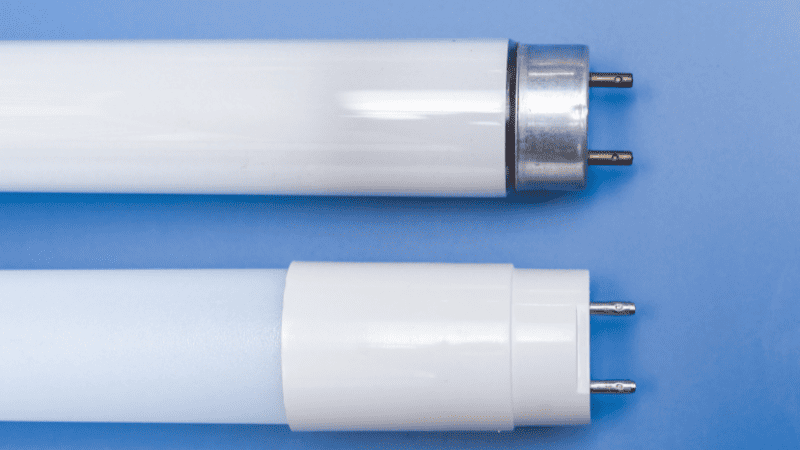

Tube lights are one of the warehouse industry’s most traditionally used and highly versatile lighting solutions.

These lighting fixtures are ideal for precise area installations and are optimally mounted at ceiling heights ranging from 8 to 10 feet. They are available in a variety of configurations to cater to diverse lighting needs:

Tube lights can be efficiently used in various sections of a warehouse. In storage areas, tube lights provide uniform and full-spectrum lighting, ensuring all products are visible and reducing the chances of misplacement or accidents.

They can also be used in assembly lines or packing stations where workers need bright, clear light for precision tasks. The aisles between racks are another ideal location for tube lights, providing clear vision and safe navigation.

As for their length, tube lights are available in standardized lengths of 2 and 8 feet. However, the length can be chosen based on the size and layout of the warehouse, with the 8-foot tubes generally preferred for larger spaces due to their extensive coverage area.

High Bay Lights are another common lighting solution dedicated to spaces with high ceilings, typically 20 feet and above, and are thus perfect for warehouses.

Designed to distribute bright light over a wide area efficiently, these fixtures are instrumental in enhancing workplace safety and productivity.

High Bay Lights are ideal for open areas in a warehouse, like loading docks or sorting areas where broad and bright illumination is crucial. They can also be effectively used in aisles with high-stacking areas requiring vertical illumination.

Various lens angles ranging from 60°, 90°, and 120° are available, allowing the light to be directed precisely as needed.

The wattage of High Bay Lights can range from 95W to 495W based on the amount of light required.

Lower wattages are generally suitable for smaller spaces or areas that do not require intense light, while higher wattages are perfect for larger warehouse areas or tasks requiring brighter illumination.

Wall Pack Lights are an effective solution for outdoor and perimeter lighting in a warehouse setting. These fixtures are mounted on the exterior walls of a warehouse, illuminating the surroundings and enhancing security and visibility during the dark hours.

Two primary types of Wall Pack Lights include:

Wall Pack warehouse lighting is commonly used in outdoor areas such as loading bays, entrances, exits, and walkways around the warehouse.

They ensure safe navigation and deter trespassing or theft during night hours. Various beam angles are available, narrow to wide, allowing the light to be directed precisely where needed.

Industrial Strip Lights are versatile and efficient warehouse lighting fixtures often employed in warehouses.

These fixtures are generally long, narrow, and easy to install at various points in a warehouse, including ceilings, walls, or even along the floor. They provide uniform and consistent illumination, ideal for long, narrow spaces like aisles or corridors.

Two common types of Industrial warehouse lighting fixtures include:

Industrial Strip Lights can be used in various warehouses, including storage, sorting, and packing. Their brightness can be adjusted according to the specific lighting requirements, ensuring optimal illumination for every task.

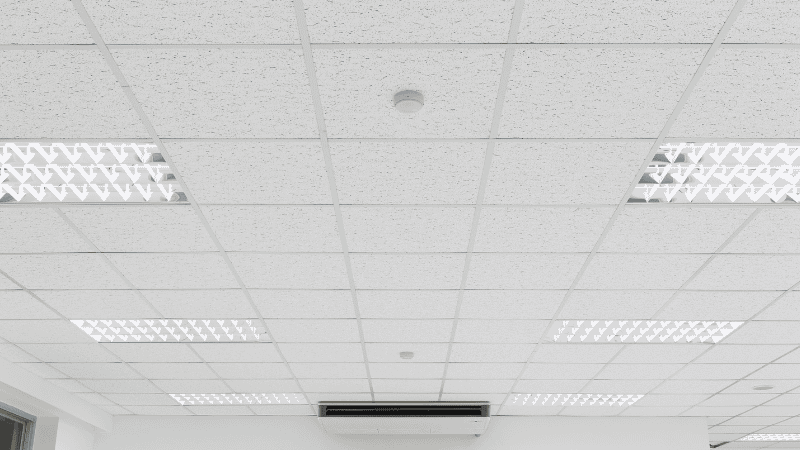

Troffer Lights are a popular choice for warehouse lighting due to their efficient and versatile design. These light fixtures are mostly rectangular in shape and are designed to fit into a modular dropped ceiling grid, or they can be surface mounted.

They offer uniform and glare-free illumination, making them perfect for areas where detailed tasks are performed.

There are two key types of Troffer Lights commonly used in warehouse settings:

Troffer Lights are often used in office spaces within the warehouse, loading areas, or any other location requiring bright lighting. The light output can be easily adjusted by using dimmable Troffer Lights to match the specific lighting requirements of the space.

Below is the table comparing the various lighting options commonly used in warehouses, highlighting their features:

| Aspect | LED | Fluorescent | HID |

| Energy Efficiency | High | Moderate | Low |

| Lifespan | Long | Moderate | Moderate |

| Maintenance | Low | Moderate | Moderate |

| Dimmable | Yes | No | No |

| Instant On | Yes | Yes | No |

| Flicker-Free | Yes | Some | No |

| Safety | Safe | Mercury content | High heat output |

LED light fixtures stand out in various aspects in terms of benefits. Firstly, they are dimmable, allowing for flexibility in adjusting the brightness level to match the specific lighting needs of the warehouse space.

This feature also increases energy savings, as the lights only use as much power as needed.

Safety is another significant benefit of LED lights. Unlike Fluorescent and HID lights, LED light fixtures produce very little heat, reducing fire risk. Further, they do not contain hazardous materials like mercury in fluorescent and HID lights.

Although the initial cost for LED warehouse light fixtures may be higher than other options, the long-term savings in energy usage and maintenance costs make them more economical in the long run.

Below are the warehouse lighting requirements and standards:

The Occupational Safety and Health Administration (OSHA) is a regulatory agency in the United States responsible for ensuring safe and healthful working conditions for working men and women. OSHA sets and enforces standards and provides training, outreach, education, and assistance.

In terms of warehouse lighting, OSHA standards require general lighting for all areas of the warehouse to ensure the safety of workers and visitors.

The lighting should be sufficient to provide an average illumination of at least 5-foot candles (54 lux) on all working surfaces.

Furthermore, areas where workers perform tasks such as reading labels or operating machinery must have local lighting to illuminate at least 10-foot candles (108 lux).

Warehouse owners or managers should conduct regular lighting audits to ensure continuous compliance with these standards and promptly replace or repair faulty lighting fixtures.

The DesignLights Consortium (DLC) is a non-profit organization that promotes high-quality, energy-efficient lighting solutions to help achieve energy and environmental goals.

The DLC provides a platform for manufacturers, utilities, lighting designers, and other industry professionals to collaborate on developing more advanced and efficient lighting products.

The DLC has set specific requirements for warehouse LED lights through its “High-Bay and Mid-Bay Specification.” The criteria ensure that warehouse LED lights meet certain standards for energy efficiency, light output, color quality, and performance.

Installing DLC-certified LED lighting ensures compliance with OSHA regulations and guarantees significant energy savings and lower maintenance costs.

Leadership in Energy and Environmental Design (LEED) is a green building certification program promoting environmentally responsible construction project practices. One of the criteria for achieving LEED certification is energy-efficient lighting.

To meet the minimum requirements for LEED certification, warehouses must have a lighting power density (LPD) of no more than 0.8 watts per square foot.

This means that for every square foot of warehouse space, a maximum of 0.8 watts of lighting should be installed.

Moreover, to earn additional points towards LEED certification, warehouses can install energy-efficient lighting fixtures with advanced features such as daylight and occupancy sensors.

In warehouse settings, lighting fixtures may be exposed to dust, moisture, and other environmental factors. Therefore, it is essential to consider the IP (Ingress Protection) rating of a lighting fixture before installation.

IP ratings indicate the protection a lighting fixture provides against foreign objects and water. The first digit in an IP rating indicates protection against solids, while the second indicates protection against liquids.

For warehouses, it is recommended to use fixtures with a minimum IP rating of 65, providing complete protection against dust and low-pressure water jets.

This ensures that the lighting fixtures can withstand harsh warehouse environments and have a longer lifespan.

As you embark on designing your warehouse lighting, consider several key tips to create an environment that meets the needs of your operations and staff.

When designing warehouse lighting, it is essential to consider light distribution patterns. Different lighting distribution patterns may be more suitable depending on a warehouse’s layout and shelving systems.

For example, if there are narrow aisles with high shelving racks, narrow beam angle lights would be more effective at providing focused lighting where needed.

On the other hand, for open areas with low shelving, wide beam angle lights would be more practical for providing general lighting.

Incorporating natural lighting into warehouse design can save energy and improve the working environment.

Skylights, windows, and translucent panels on the roof allow natural light to enter the warehouse during the day, reducing the need for artificial lighting.

Furthermore, natural light can improve the well-being and productivity of workers by providing a more comfortable and visually stimulating environment.

The ceiling height of the warehouse determines the type of lighting fixtures that will be needed. LED high bay lighting is recommended for warehouses with high ceilings as they provide bright and uniform lighting from a higher position.

On the other hand, for warehouses with low ceilings, LED linear strip lights or troffers would be more appropriate as they can be mounted closer to the ground.

The color temperature of lighting can also impact the working environment. For warehouse tasks that require high concentration and accuracy, a cooler color temperature (5000K-6500K) is recommended as it mimics natural daylight and improves visual acuity.

Alternatively, for areas where workers may need to relax or take breaks, a warmer color temperature (2700K-3500K) can create a more relaxed and comfortable atmosphere.

One-size-fits-all lighting solutions may not work for different areas in a warehouse. Depending on the location and function of each area, specific lighting requirements should be considered.

Here are some examples of different lighting solutions for various locations in a warehouse:

Utility and storage rooms typically require low lighting as they are not frequently occupied. Installing LED strip lights or troffers can provide enough light for workers to navigate and perform maintenance tasks in these areas.

Loading docks and shipping areas require bright and uniform lighting to ensure the safe loading and unloading of goods. LED high bay light fixtures with a wide beam angle are recommended to provide ample light in these areas.

Workshops in a warehouse require bright and focused lighting for detailed tasks such as assembly and repairs. LED linear high bay light fixtures with a narrow beam angle are ideal for these areas, providing targeted light to specific workstations.

These lights offer long-lasting performance, reducing the need for frequent replacements and maintenance.

Lighting the exterior walls of a warehouse is important for security and safety purposes. LED wall packs or floodlights can be installed to provide bright and long-lasting lighting along the warehouse’s perimeter, deterring potential intruders and ensuring workers’ safety during night shifts.

LED high bay lights with a wide beam angle are recommended for open-area warehouses, and a lighting level of 100 Lux is suitable. LED linear high bay lights with a narrow beam angle are preferred for narrow aisle warehouses, and a lighting level of 200 Lux is recommended.

The spacing of LED warehouse lights can vary depending on the height of the ceiling. For ceilings that are 20 feet or less in height, a spacing between 20 and 30 feet is recommended. For taller ceilings, a spacing between 30 and 40 feet is recommended for optimal lighting coverage.

According to the Occupational Safety and Health Administration (OSHA), lighting in warehouses should provide a minimum of 5 candles (54 lux) for general illumination and 10 candles (108 lux) for specific tasks.

Maintaining proper lighting in a warehouse is crucial for ensuring the safety and productivity of workers, as well as saving on energy costs.

By considering natural lighting, ceiling height, color temperature, and regular maintenance, warehouse owners can create an efficient and safe working environment for their employees.

At Risun, we provide high-quality LED lighting solutions for warehouses and industrial spaces.

Our experienced team can assist you in choosing the most suitable lighting options for your specific needs and offer energy-saving solutions that will help reduce costs in the long run.

Whether you are looking for linear high bay lights, UFO high bay lights, or wall packs, we have many options. Contact us today, and let us help you improve the lighting in your warehouse!

Comprehensive Lighting Solutions for MRO Wholesalers and Professionals

send your inquiry

Hi, I'm the author of this post, and I have been in this field for more than 15 years. If you want to wholesale lighting fixtures or lighting related product, feel free to ask me any questions.

Learn More >>Download our catalog to view all of our lighting products.

Ready to get started ?

Send Your InquiryOur team will get back to you promptly

please

download

Get notified about new products

Our team will get back to you promptly!

Add your first comment to this post